10-2000tpd Palm Kernel Oil Extraction Machine Palm Oil Pressing Production Plant

- usage: Palm Oil

- max capacity: 1000kg/h

- weight: 100000

- warranty: 6 Months

- oil type: Palm Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 5-500T/H

- key selling points: Sustainable

- Product name: Palm kernel oil extraction machine palm oil pressing production plan

- Application: Edible Oil Production

- Advantage: High Oil Output

- Keyword: Palm oil pressing machine

- Certification: ISO9001:2008

- Raw material: Palm fruit, Palm kernel, Palm oil

- Feature: Effecient

- Capacity: Large

- Character: Professional Manufactuer

- Method to press: Screw Squeezed Press

- Selling Units: Single item

- Single package size: XX cm

Palm kernel oil pressing extraction machine plant palm fruit oil production line

Our company is specialized in palm oil extraction machine, we can provide the palm oil extraction machine from 10 ton to 3000 tons per day capacity.

Workshop section of palm kernel oil pressing extraction machine plant palm fruit oil production line

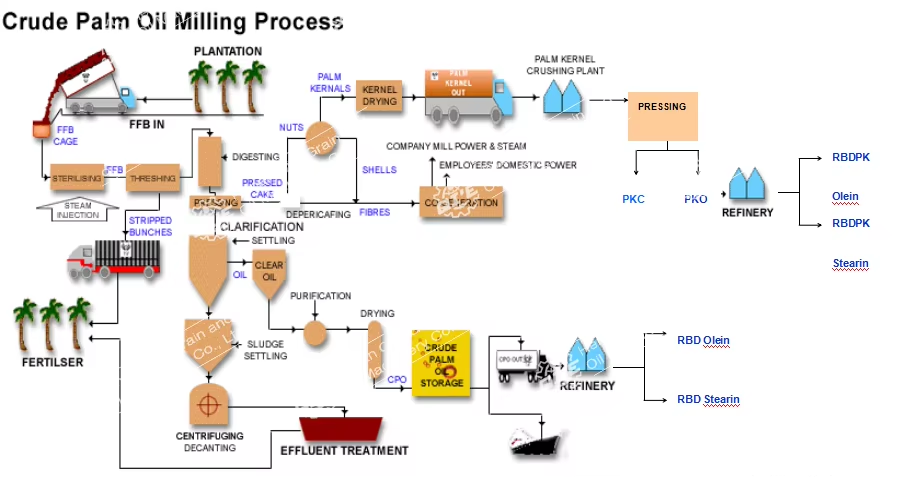

Diesel Generator→ Steam Turbine→ Reception Station→ Palm Oil Plant Sterilizing Station→ Thresher→ Press Station→ Pressing station→Screen Filter→ Decanter Centrifuge→Vacuum Dryer→ Sewage Treatment

Diesel generator

Steam turbine

Reception Station

Sterilizing station

Thresher

Press station

Screen filter

Decanter Centrifuge

After transport the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm fruit cage. After separating palm fruits and palm bunch by thresher, Pam fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel. After pressing, we can get palm cake and palm nut. Pam nuts will be conveyed to palm recovery system to get palm kernels, fiber and palm shell. Palm cake will be conveyed to boiler room as fuel. After filtering, centrifuging, vacuum drying, we can get crude palm oi (CPO), the CPO can be sold directly or used for further processing. The sewage from all the plant will be processed by sewage treatment to reach discharge standard. Sludge can be used for fertilizer in palm plantation. All the process cycle features with short operation cycle, high automaticity, energy conservation and environmental protection.

Features of palm kernel oil pressing extraction machine plant palm fruit oil production line:1 Compact and strong structure, and easy operation. 2 The automatic control system which can adjust barrel pressure. 3 High oil pressing efficiency, and residual oil in cake is less than 8%. 4 Low crushing efficiency for palm nut. 5 Invest is small, quick gains.

| crude oil moisture content | ≤0.1-0.2% |

| Impurity content of crude oil | ≤0.2% |

| Palm kernel moisture | ≤ 8% |

| Husk content of palm kernel | ≤2.0% |

Palm Oil refining: crude oil – degumming & dephosphorization – deacidification – drying – decolorization – deodorization – defatting – dewaxing – finished oil.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems. If the amount of goods to be delivered is relatively small, the goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company Profile

HENAN QIE MACHINERY CO.,LTD is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R&D and application of new technologies.

Our Service

Service before sale

1. 24 hours online.Your inquiry will be quickly replied by email. Also all questions with you can be solved by any online chatting tools.

2. Professionally and patiently introduction, details pictures and working video to show machine.

Service on sale

1. Installation: quality and quantity guaranteed; completion of hand over.

2. Acceptance: acceptance test; accepted deliverables.

3. Technical training: on-site installation and products training.

Service after sale

1. Technical service: long time technical service.

2. Accessories supplying: supplying spare parts with cost price.

3. Client review: call-back; regular return visit.

4. 24 hours online to solve any problem .