20 Ton Per Day Palm Kernel Oil Press Complete Production Line in Nigeria

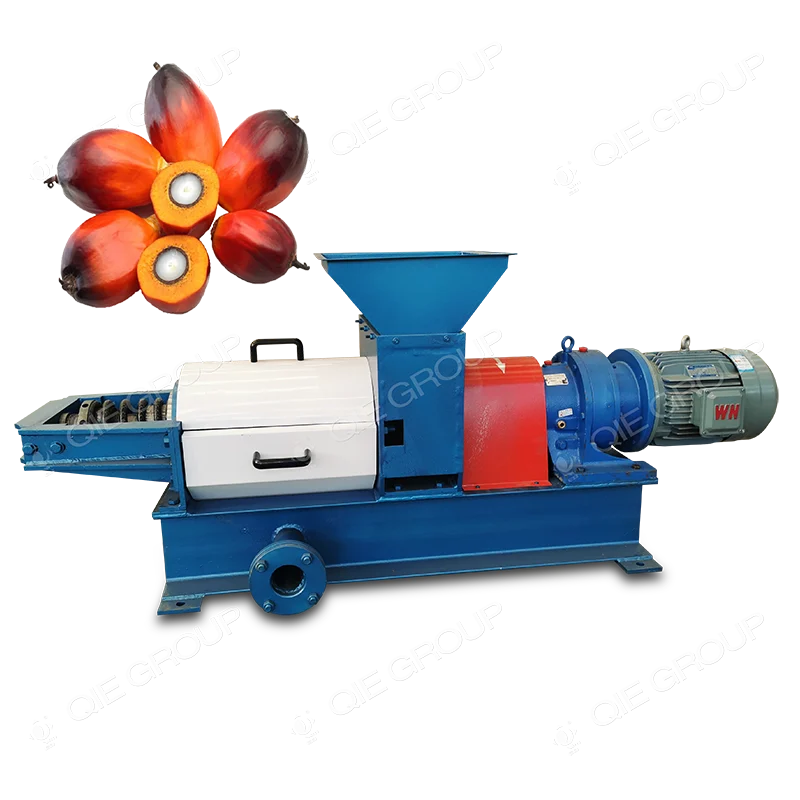

- usage: Palm Oil Extracting

- max capacity: 2000tpd

- weight: 15300 KG

- warranty: 1 Year

- oil type: Palm Oil, Crude Palm Oil, Refined Palm Oil

- type: Easy Maintenance Palm Oil Plant

- automatic grade: Automatic

- production capacity: 88 Sets Monthly

- voltage: 380V/440V

- dimension(l*w*h): Depends On Capacity

- key selling points: Famous brand PLC Palm Oil Plant

- Product name: palm oil press project

- Raw material: Palm Kernel,Palm fruit

- Advantage: Energy Saving

- Application range: Palm oil extraction and refinery

- Custom solution: Yes

- Material: 304 Stainless Steel

- Used for: Pressing Palm Oil

- MOQ: 1 set

- Color and logo: custom

- Selling Units: Single item

- Single package size: XX cm

20 Ton Per Day Palm Kernel Oil Press Complete Production Line in Nigeria

Main service of palm oil processing machine:

1TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

2-10TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

15-30TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

40-100TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

5-1000T/D palm oil refinery project production;

5-1000T/D palm oil fractionation project production;

QI’E Palm Project Cases

Processing Design

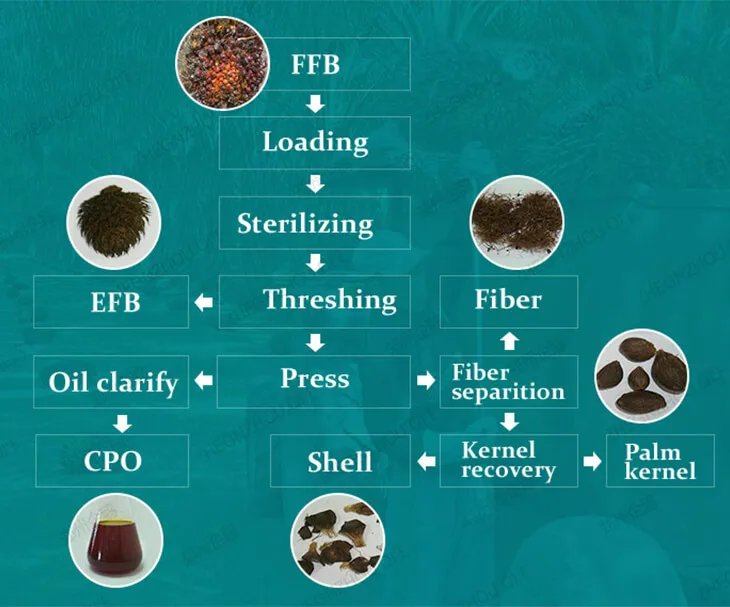

Processing Procedure

20 Ton Per Day Palm Kernel Oil Press Complete Production Line in Nigeria

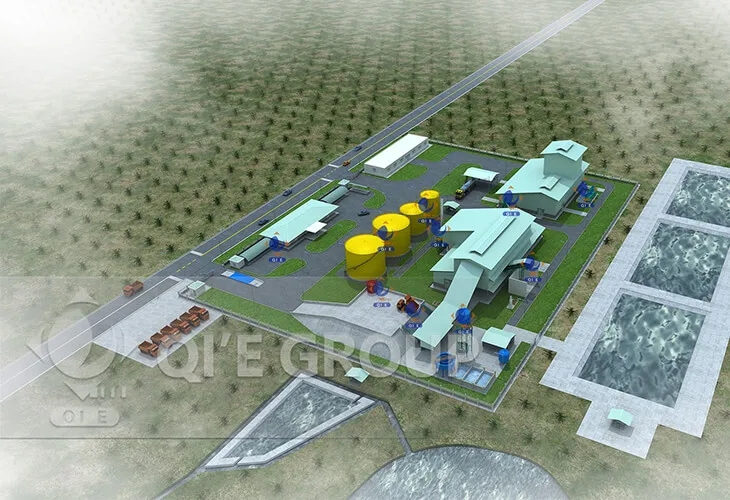

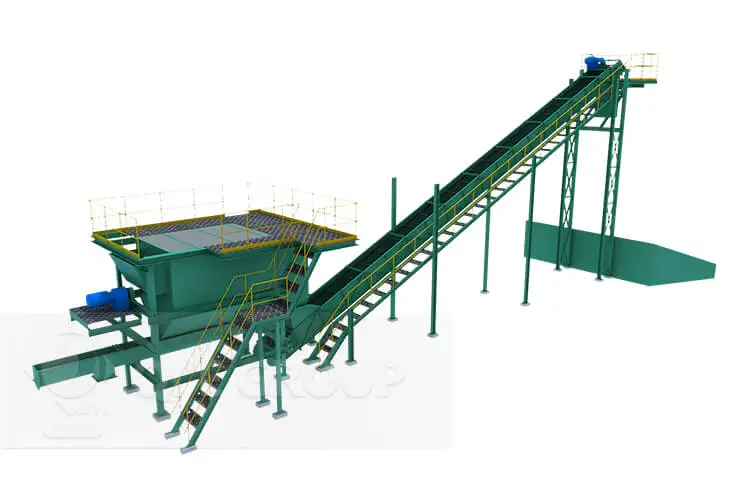

Palm oil factory 3d design sketch

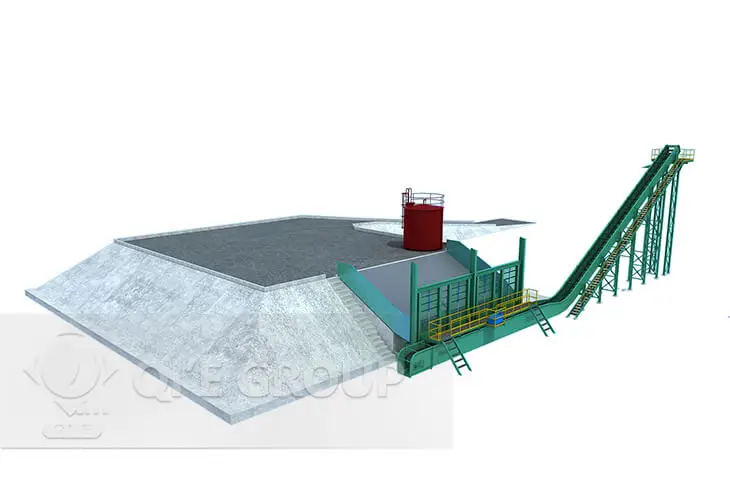

01. Raw material reception station:

The fresh palm fruit bunches are sent into the factory through the weighbridge to weight the raw materials and to calculate the production cost. Palm bunches reception process is finished at loading ramp. This loading ramp makes palm fruit unloading,cleaning, storage platforms, adopting all hydraulic segmented discharge.

02. Sterilizing station:

After being transported to the sterilizer, steam will be injected directly inside to weaken the activity of the enzyme, which prevents it getting rancid, to ensure the high quality of the pressed crude palm oil. Meanwhile, it is soft enough for later threshing processing. We have designed both horizontal and vertical sterilizer for larger and smaller line.

03. Threshing station:

The rotating drum in the thresher separates palm fruits from the bunches. Palm fruit will be conveyed to the digester through elevator, the empty bunch to the outside part through scraper conveyor. Spindle adopts on time forging technology, it makes the equipment solider and more durable. Non spindle thresh is also designed, it is driven by the link chain. It can save the producing cost in a large scale palm oil plant.

04. Digesting & pressing station:

The digester is used to adjust moisture and temperature of the palm fruit, finally to increase the extraction rate of the palm oil. The digester adopts liquid level control system, which can distribute the material all by itself. To realize the automatic working.

The presser adopts hydraulic control system to adjust the distance of different pressing worms, it is applicable to different kinds of palm fruits, and it can ensure the high oil extraction rate.

The palm fruit oil yield increase by adjusting material moisture and temperature in digesting tank.digesting tank uses liquid

level control, so material can distribute automatically and equipment runs fully automatically. Pressing machine uses hydraulic control system to adjust spacing between pressing bolts. So it can be suitable for various palm fruit species and guarantee the oil yield.

05. Clarification station:

Using the latest technology, under the condition of ensuring the good quality of the oil, reduce the equipment cost as much as possible, reduce the loss of the oil, in the practical producing ,the new technology can make the loss of oil less than 1.3%.

06. Palm Kernel recycling:

After pressing, the palm kernel and fiber mixture can be processed by further separation. After drying, the palm kernels are stored for deep processing, and the separated fiber and shells are used as the boiler fuel for providing steam.We provide custom design based on your budget, land and later upgrading on capacity.Any interest, pls click here to contact us!

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.1. More than 30 years of experience2.Top production team3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!