20tph Cotton Seeds Oil Extraction Machine Cottonseed Oil Production Line

- usage: Cotton Seed Oil Production

- max capacity: 2000tpd

- weight: 1200 KG

- warranty: 1 Year

- oil type: Crude Cotton Seed Oil, Refined Cotton Seed Oil, cotton seed oil

- type: Multi-functional Cotton Oil Plant

- automatic grade: Automatic

- production capacity: 100 Sets Monthly

- voltage: 380V or 440v

- dimension(l*w*h): Depends On Capacity

- key selling points: Long Service Life Cotton Oil Production Line

- Processing Material: Sunflower, Soybean, Sesame, Peanut, Mustard, Canola and etc.

- solvent: n-hexane

- Machinery type: Cotton Seed Oil Extraction Machine

- Residual oil in meal: 1%

- Feature: High Oil Yield Efficiency

- Advantage: Energy Saving

- Material: 304 Stainless Steel

- keyword: oil solvent extraction

- Custom solution: Yes

- Capacity: 10TPD-2000TPD

- Selling Units: Single item

- Single package size: XX cm

20TPD cotton seeds oil extraction machine cottonseed oil production line

Capacity: 30T-2000T/D

Oilseeds scope: cotton seed, soybean, rice bran, peanut, sesame, sunflower seed, rapeseed, cottonseed, corn germ, copra, castor bean and so on.

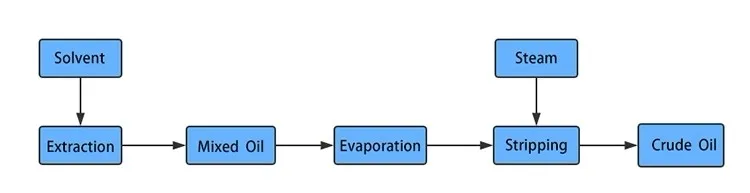

The extraction process:

Extraction: It usually adopt an organic solvent that can dissolve the oil, through the material spray, soak, so that the oil will be extracted from the oil-bearing seeds.

DTDC: By continuously the multi-layered steam heating, the heat obtained by the solvent in the wet mash is vaporized, thereby separating the solvent from the wet meal, and removing the solvent remaining in the wet meal as much as possible.

Evaporation: The difference between the boiling point of the oil and the solvent is used to separate the solvent and the oil.

Stripper: The separated solvent can be dissolved in the selected paraffin or solvent and recovered.

Extraction

DTDC

Evaporation

Stripper

The Case

20TPD cotton seeds oil extraction machine cottonseed oil production line

Parameters

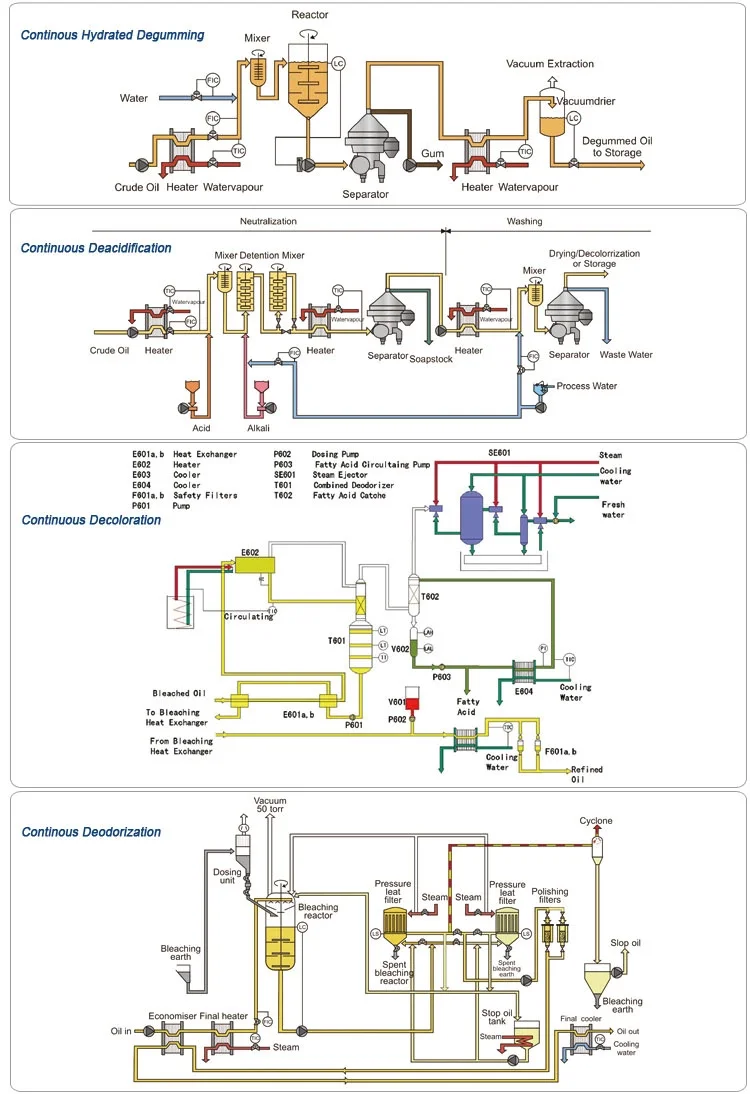

20TPD cotton seeds oil extraction machine cottonseed oil production line

| Alkali | Oil acid valuex1-3kg/T oil |

| Refining rate | 1-refining consumption |

| Water (soften water) | 150Kg/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Steam consumption | 700KG/T oil |

| Circulating water cooling water yield | 150M3/H |

| Bleaching earth consumption | 3-5Kg/T oil |

| Waste bleaching earth oil content | ≤25~35% |

| Refining losses | Acid valuex1.2 (chemical refining)Acid valuex 0.6 (physics refining) |

| Bleaching losses | The quantity of bleaching earth×0.25% |

| Electric consumption | 28Kwh/T oil |

| Deodorization loss consumption | ≤0.5% |

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

The factory is located in Henan Province, China. We are very welcome to visit our factory. If you need it, we will arrange a pick-up.

2.Top production team

The transportation and packaging will be packaged in international standards. If you have special packaging requirements, we will give you the most suitable solution.

3.High quality products

Our sales manager will send you a production progress picture or video every day, so that you can know the production progress of the product in real time, and we accept L/C payment.

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!

Our Service

Pre-sale services

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

After-sale services

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipment;

3) Training the first-line operators on site;

4)Supplying spare parts with cost.