Complete Set Palm Fruit Oil Press Machine Palm Oil Processing Plant in Indonesia

- usage: Palm Oil

- max capacity: 2000tpd

- weight: 1530 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: Palm Oil Project

- automatic grade: Automatic

- production capacity: 100 Sets/Month

- voltage: 220V/380V/440V

- dimension(l*w*h): depends on capacity

- key selling points: High Productivity

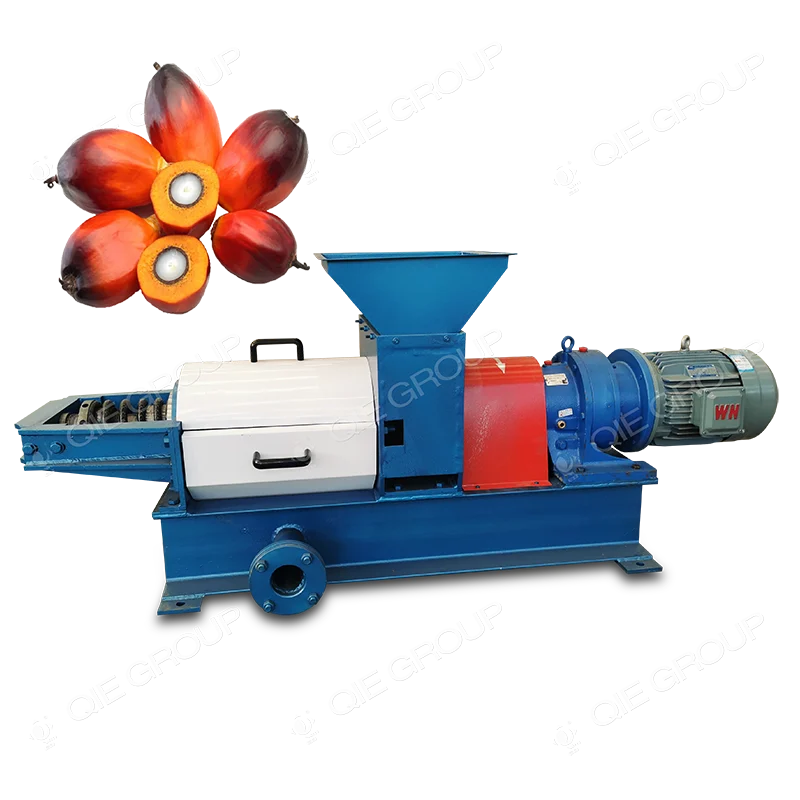

- Product name: double screw palm oil press plant

- Raw material: Palm Kernel,Palm fruit

- Advantage: Energy Saving

- Application range: Palm oil extraction and refinery

- Custom solution: Yes

- Material: 304 Stainless Steel

- Used for: Pressing Palm Oil

- MOQ: 1 set

- Color and logo: custom

- Selling Units: Single item

- Single package size: 5X2X3 cm

- Single gross weight: 0.500 kg

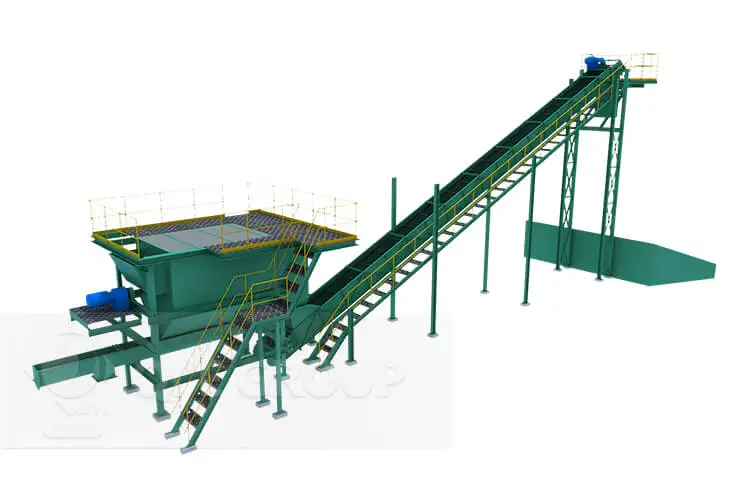

Complete palm oil processing plant

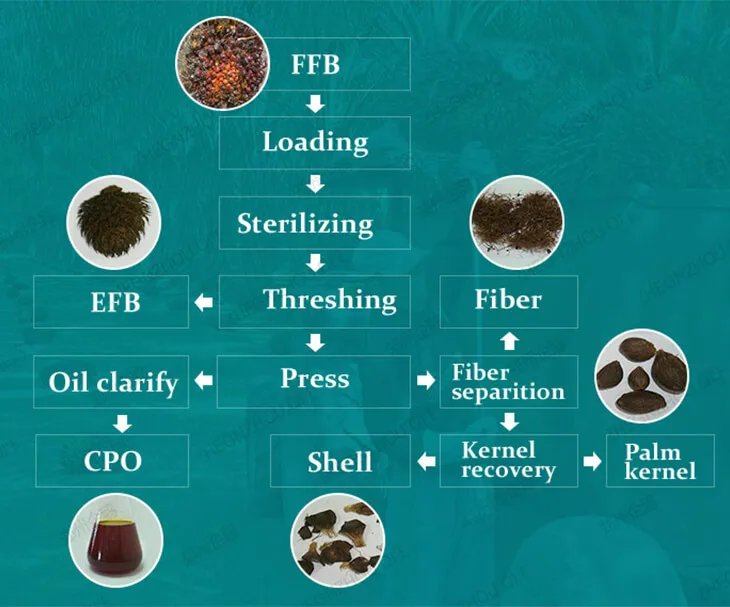

Palm fruit oil press line palm oil press processing extraction machine line with 1~10 ton per day production output, the total processing , including threshing, digesting and sterilizing, oil pressing and oil filtering. One of the reasons of small scale palm oil mill are very common in the global market including is that they are affordable and they are enough to produce sufficient amounts of palm oil for local business.

Processing Design

Processing Procedure

Complete palm oil processing plant

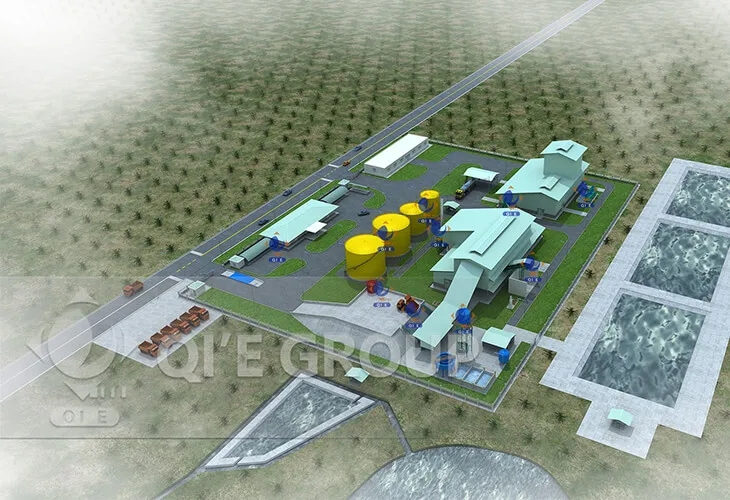

Palm oil factory 3d design sketch

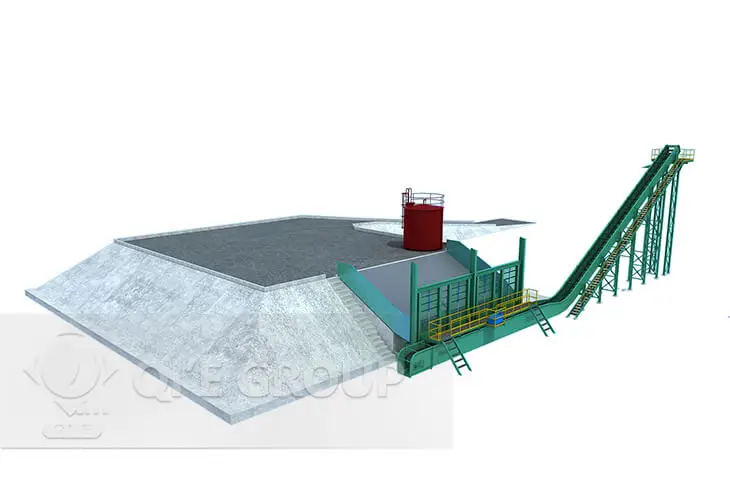

01. Raw material reception station:

Used for loading fresh palm fruit brunch from plantation, transport to sterilizer.

02. Sterilizing station:

The palm fruits are subjected to high temperature cooking for about 60 minutes by hot water (about 100 ℃) to destroy the lipase in the fruit to avoid the increase of free fatty acid content in the oil. In addition, high temperature killing can make the fruit soft, which is beneficial to the subsequent shelling of the core and reduce the damage of the kernel.

03. Threshing station:

Stripper is widely used in mini and small palm oil extraction mill. The palm fruits account for about 60% of the whole fruit bunch, and the purpose of threshing is to separate palm fruit from the fruit bunch. There is equipped with a lightweight rod in the thresher. When the drum rotates, the palm fruit bunch moves upwards and then falls under

the force of gravity, so that palm fruit vibrates from the fruit bunch. The drum is continuously turned over until it is discharged from the bottom

04. Digesting & pressing station:

They are mainly to crash palm fruit and then press. Crude palm oil can be got at this station.Screw pressing is the main method of palm oil extraction. In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts.

05. Clarification station:

The purpose is to remove some fiber, mud, or other impurities. After clarification, the purified palm oil can be directly sold or deeply refining.

06. Palm Kernel recycling:

After pressing, the palm kernel and fiber mixture can be processed by further separation. After drying, the palm kernels are stored for deep processing, and the separated fiber and shells are used as the boiler fuel for providing steam.We provide custom design based on your budget, land and later upgrading on capacity.Any interest, pls click here to contact us!

Indonesia Vertical Sterilizer for Palm Oil Mill Processing Machine

- High Safety Level and Efficiency: This Indonesia vertical sterilizer for palm oil mill processing machine ensures a high level of safety and efficiency in the food industry. With a high safety level, you can rely on this machine to produce quality products while minimizing risks.

- Durable and Long-Lasting Construction: Made from high-quality stainless steel (SUS304/316), this machine boasts a robust and long-lasting construction, capable of withstanding the demands of continuous use in various industries such as manufacturing plants, food & beverage factories, and farms.

- Low Energy Consumption: As a user mentioned in our previous conversation, this machine operates with a low energy consumption, making it an ideal choice for industries looking to reduce their energy bills while maintaining high productivity.

- Advanced Technology: Equipped with a PLC and pressure vessel, this machine features a fully automatic control system, ensuring efficient and reliable operation. The 2-year warranty on core components provides added peace of mind for our customers.

- Global Availability and Support: With showrooms located in Italy, France, Germany, Indonesia, Russia, and Australia, our customers can enjoy local support and service. Furthermore, our team of engineers provides after-sales service to ensure seamless operation and minimize downtime.

QI’E Palm Project Cases

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.1. More than 30 years of experience2.Top production team3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!