High Quality Palm Oil Milling Plant Palm Kernel Oil Machine in Brazil

- usage: palm oil

- max capacity: 2000TPD

- weight: 500 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: Multi-functional Palm Oil Project

- automatic grade: Automatic

- production capacity: 88 Sets Monthly

- voltage: 380V, 440V

- dimension(l*w*h): depend on the capacity

- key selling points: High Productivity Palm Oil Project

- After-sales Service Provided: Engineers available to service machinery overseas

- Name: Palm Oil Milling Plant

- Raw Material: Palm Kernel, Palm, etc

- Function: Making Edible Oil

- Advantage: Energy Saving

- Application: Palm Oil Processing Machine

- Product Name: Palm Oil Milling Process Palm Kernel Cake Oil Machine

- Material: Stainess Steel

- Color: Clients' Requirements

- Warranty: 12 months

High Quality Palm Oil Milling Plant Palm Kernel Oil Machine in Brazil

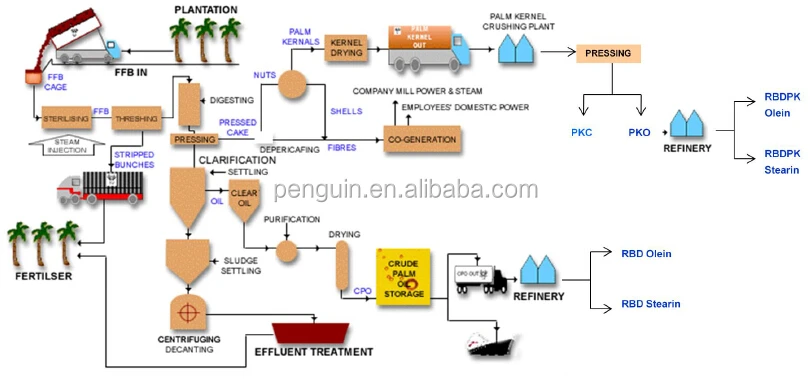

Palm oil is easily digested, absorbed, and promotes health. Palm oil is an important ingredient in fat and has a mild property and is a good material for making food. From the combination of palm oil, its high solids glycerin content keeps the food stable from hydrogenation and effectively resists oxidation. It is also suitable for the hot climate to become a good condiment for pastry and bakery products. Due to several properties of palm oil, it is very popular among food manufacturing.We have low environment pollution palm oil milling production line. This palm fruit oil machine adopts process of sterilization, threshing, digesting, pressing, clarification, purification, drying, depericarper, crushing and final press-ing. This mature design fulfills the lowest fuel consumption, steam driving, and self-sufficient energy supplying.Quality and performance reliable and stable oil making process. The design, manufacturing, and installation are all CE and ISO quality approval. Our have rich experience in palm oil making machine designs and gets national patent certificates of multiple oil milling production lines.

The process of palm oil milling plant process palm fruit→palm loading station→palm sterilizing station→palm threshing station→palm pressing station→palm separation of shell kernel→boiler room→kernel oil press→oil clarify→water treatment

The Fresh Fruit Bunches(FFB) is available after 3 yeas plantation. Palm fruits are sent into crude palm oil processing plant with following production process:

(a)Weighing. Transport palm fruit to factory after truck weighing so as to make prompt settlement and production cost subsequent.

(b)Unloading fruit. Fresh Fruit Bunches (FFB) are sent to fermentation tank through transportation machinery after sieving and impurities removing. The time from picking up to fermentation should be less than 24 hours, or the free fatty acid(FFA) will rise, which will not be conductive for further processing and production of palm oil from palm oil making machine.

(c)Sterilization. FFB will pass high pressure and high temperature sterilization after entering fermentation tank. It will soft and make sterilization for FFB.

(d)Threshing. Threshing machine will separate both palm fruits and empty fruit bunches(EFB) after FFB soften during fermentation.

(e)Empty fruit bunches (EFB). EFB are sent to send to garden as fertilizer, fuel or other purposes after conveying and hoarding.

(f)Meshing. Mixing tank will mesh and crush palm fruit until broken after fruit threshing.

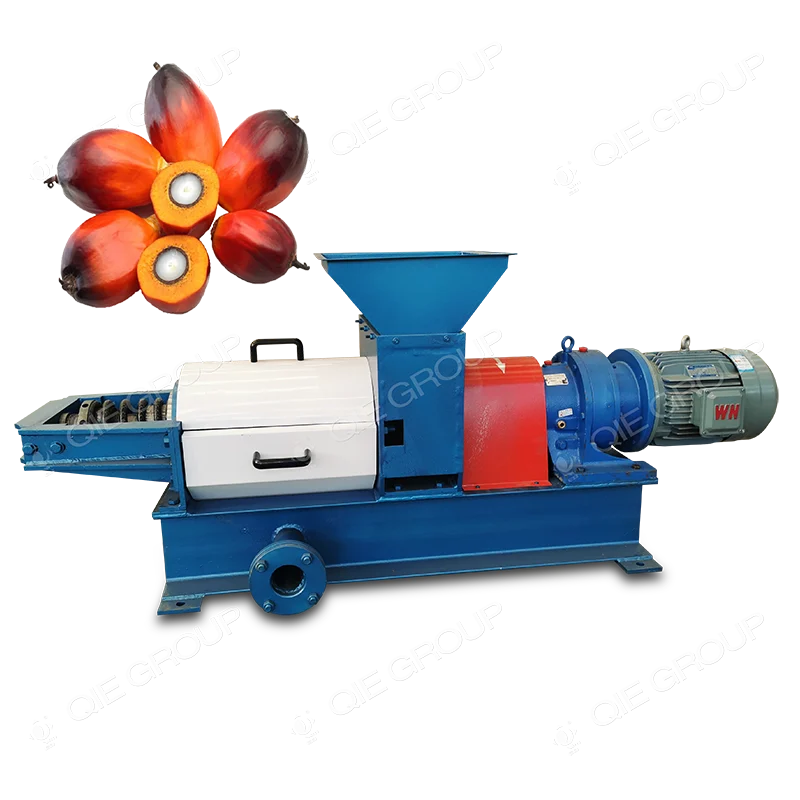

(g)Pressing. The crushed palm fruit will be leaching out from screw extrusion of palm oil pressing machine.

(h)Fiber separation. The extruded fiber pie enters air separation system after crushed to get separation of fibers and cores.

(i)Separation. Crusher divided fruit core into palm kernel and shell after separated with fiber. Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

(j)Oil clarification. Crude palm oil (CPO) contains moisture and impurities after palm oil pressing. CPO begins primary treatment through sand tank and screen, enters vertical clarification tank to make heating and stirring, and finally separate into waste oil and edible vegetable oil. Edible vegetable oil is sent to crude oil storage tank after drying.

(k)Oil transportation. Oil pipeline transportation will be projected on basis of present situation.

(l)Water treatment. Water source is introduced into plant from river nearby. It will achieve boil feed water standard after primary clarification and filtration, secondary osmosis and reverse osmosis treatment.

(m)Power system. Steam turb generator power generation is the main driving force. It is also equipped with diesel generator sets.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!