Palm Oil Processing Plant Palm Oil Pressing Machine Equipment Line In Africa

- usage: Palm Oil Production

- max capacity: 2000tpd

- weight: 1530

- warranty: 1 Year

- oil type: Palm Oil, Crude Palm Oil, Refined Palm Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 88 Sets Monthly

- voltage: 380V/440V

- dimension(l*w*h): Depends On Capacity

- key selling points: Turnkey Palm Oil Project

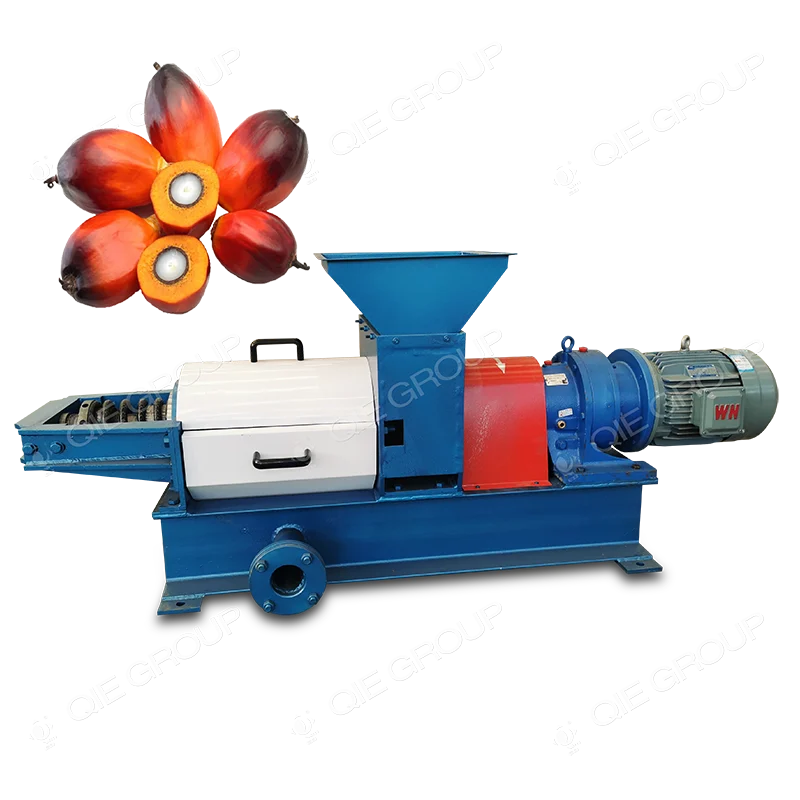

- Product name: Palm red oil press plant

- Raw material: Palm Kernel,Palm fruit

- Advantage: Energy Saving

- Custom solution: Yes

- Application range: Palm oil press line

- Material: 304 Stainless Steel

- Used for: Pressing Palm Oil

- MOQ: 1 set

- Color and logo: custom

- Selling Units: Single item

- Single package size: XX cm

Palm Oil Processing Plant Palm Oil Pressing Machine Equipment Line In Africa

Main service of palm oil processing machine:

1TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

2-10TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

15-30TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

40-100TPH palm fresh fruit bunch press project equipment manufacture,installation and Turnkey project;

5-1000T/D palm oil refinery project production;

5-1000T/D palm oil fractionation project production;

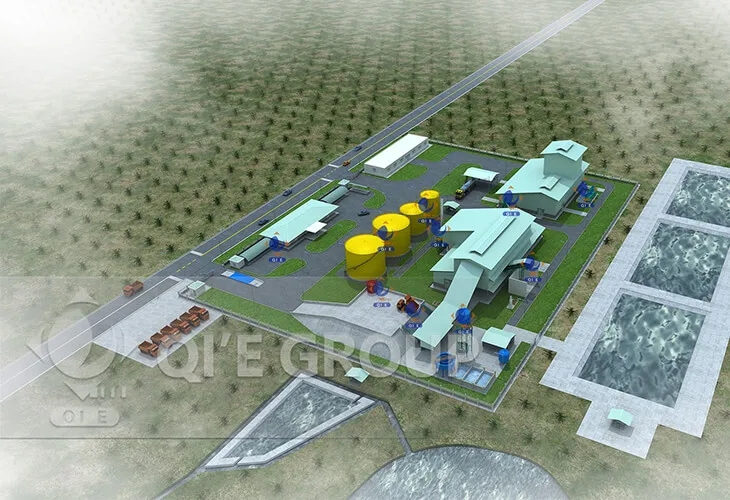

QI’E Palm Project Cases

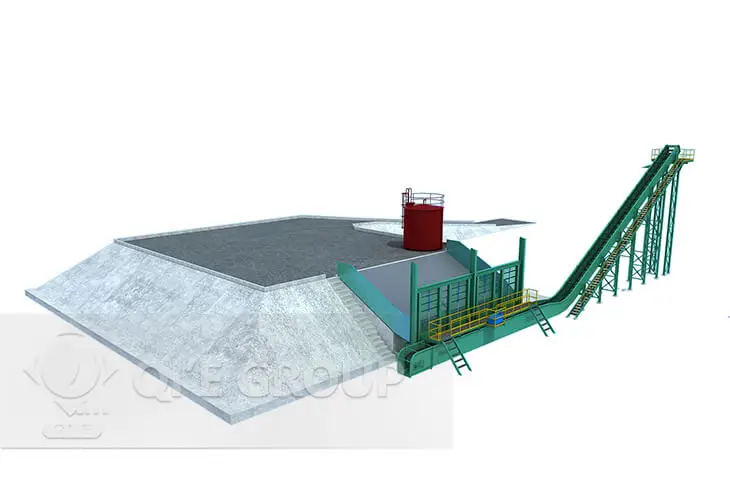

Processing Design

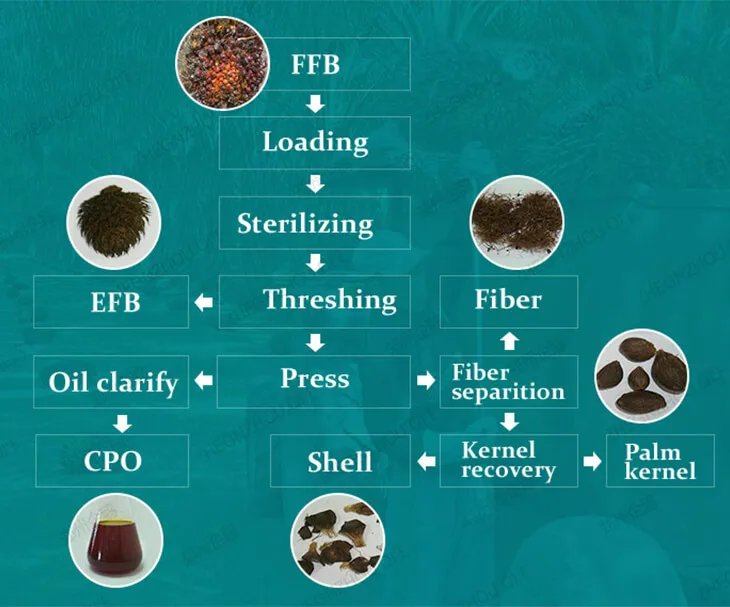

Processing Procedure

Palm Oil Processing Plant Palm Oil Pressing Machine Equipment Line In Africa

Palm oil factory 3d design sketch

FFB Process: After transporting the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm fruit cage. After separating palm fruits and palm bunch by thresher,Palm fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel. After pressing,we can get palm cake and palm nut. Pam nuts will be conveyed to palm recovery system to get palm kernels, fiber and palm shell. Palm cake will be conveyed to boiler room as fuel. After filtering,centrifuging, and vacuum drying, we can get crude palm oi (CPO), the CPO can be sold directly or used for further processing. The sewage from all the plant will be processed by sewage treatment to reach discharge standard. Sludge can be used for fertilizer in palm plantation. All the process cycle features with short operation cycle, high automaticity, energy conservation and environmental protection.

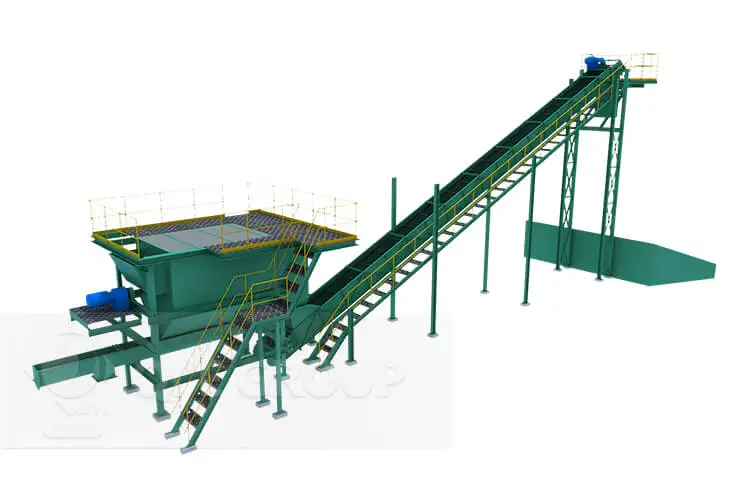

01. Raw material reception station:

Used for loading fresh palm fruit brunch from plantation, transport to sterilizer.

02. Sterilizing station:

The purpose is to break the enzymes in fruit, and to avoid the increase of the FFA content in oil. At the same time, the high temperature makes the fruit soft.

03. Threshing station:

Used to separate palm fruit seeds and the empty palm fruit bunch.

04. Digesting & pressing station:

They are mainly to crash palm fruit and then press. Crude palm oil can be got at this station.

05. Clarification station:

The purpose is to remove some fiber, mud, or other impurities. After clarification, the purified palm oil can be directly sold or deeply refining.

06. Palm Kernel recycling:

After pressing, the palm kernel and fiber mixture can be processed by further separation. After drying, the palm kernels are stored for deep processing, and the separated fiber and shells are used as the boiler fuel for providing steam.We provide custom design based on your budget, land and later upgrading on capacity.Any interest, pls click here to contact us!

Product Specification

| Capacity : | 15 TPH | Oil extraction rates : | 20~22% |

| Oil content in FFB : | ≥24% | Kernel content in FFB: | 4% |

| shell content in FFB : | ≥6~7% | Fibre content in FFB : | 12~15% |

| Empty bunch content in FFB: | 23% | Press cake proportion in FFB: | 24 % |

| Oil content in empty bunch |

5 %

|

Moisture in empty bunch :

|

63 % |

| Solid phase in empty bunch: | 32% | Oil content in press cake | 6 % |

| Water content in press cake : | 40 % | Solid phase in press cake : | 54 % |

| Oil content in nut: | 0.08 % | Oil content in wet meter heavy phase: | 1% |

| Oil content on meter solid: | 3.5% | Oil content in final effluent: | 0.6% |

| Fruit in empty bunch: | 0.05% | Total in losses: | 1.5% |

| Extraction efficiency: | 93% | Kernel Recovery efficiency: | 93% |

| Kernel in empty bunches: | 0.05% | Kernel content in cyclone fiber: | 0.15% |

| >Kernel content in LTDS: | 0.15% | Kernel content in dry shell | 2% |

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.1. More than 30 years of experience2.Top production team3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!