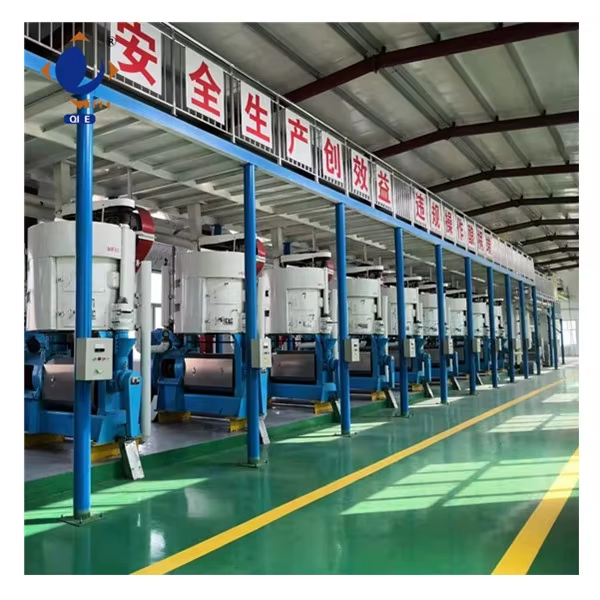

Ligne de production d’huile de sésame

- Utilisation : Production d'huile de tournesol

- Capacité maximale : 1 000 t/j

- Poids : 20 000 kg

- Garantie : 1 an

- Type d'huile : Huile de soja, huile de sésame, huile de tournesol, huile d'arachide, huile de coco, huile de son de riz

- Type : Usine d'huile de sésame facile à utiliser

- Qualité automatique : Automatique

- Capacité de production : 100 ensembles par mois

- Tension : 380 V ou 440 V

- Dimensions (L x l x H) : Selon la capacité

- Principaux arguments de vente : Usine d'huile de sésame multifonctionnelle

- Application : Ligne de production d'huile de sésame

- Fonction : Machine de production d'huile comestible

- Avantage : Économie d'énergie

- Mot-clé : Ligne de production d'huile de son de riz

- Capacité : 10-1 000 t/j

- Matériau de l'équipement : Acier inoxydable ou acier au carbone

- Matières premières appropriées : Légumes, son de riz, tourteaux d'huile de palme, graines de tournesol, etc.

- Taux d'huile : 45 % à 60 %

- Couleur : Acier inoxydable

- Certificat : CE

- Vente Unités : Article unique

- Taille de l'emballage unique : XX cm

Sesame Seed Oil Solvent Extraction Plant Sesame Oil Production Line

Sesame Peanut Oil Extractor Production Line mainly including: Oil Pretreatment and Prepressing equipment, Oil Extraction equipment, and Oil Refining equipment. We adopt different machine types, and we adopt D.T.D.C Desolventizer machine, Full negative pressure evaporation and paraffin recycling equipment at the same time. Equipment are of high quality, advanced technology, high safety, interlocking control, automatic control, stable operation, low consumption, low oil residue, and high quality final products.

| Residual oil in cake | ≤5% |

| Handling Capacité | 500kg-50tons/h |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Consommation de vapeur | ≤120Kg/T (0.8MPa) |

| Mechnical impurities | ≤ 0.3% (adjustable) |

| Moisture in crude oil | ≤ 0.2% (qualified detonated experiment |

1.Oil Pretreatment

Oil seeds — Magnetic box– Cleaning Sieve– Crusher — Flaking roll — Cooker — Oil prepressing — Cakes — Solvent Extraction workshop

2.Craft flow of solvent extraction plant

Solvant– Extracteur–Huile mixte — 1ère et 2ème évaporation — Tour de stripping — Pétrole brut

| Moisture of extraction material | 5-8% |

| temperature of extraction material | 50-55°C |

| oil content of extraction material | 14-18% |

| thickness of extraction cake | less than 13mm |

| powder porosity of extraction material | less than 15% (30 mesh) |

| solvent | national standard No. 6 solvent oil |

| volume of supplement water | 1-2m/t raw material |

3.Craft flow for refining workshop

crude oil → degumming&dephosphorization → deacidification → drying → decolorization → deodorization → defatting → dewaxing → finished oil.

(1)Deacidification and dégommage

This step is mainly to remove the excess acid in the grease. If the peptized impurities of the oil are not removed, the excessive emulsification will occur during the alkali refining process, so that the oil soap can not be separated well, affecting the refining and Oil quality.

(2)Decolorization

The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil. in this process, the oxide is completely removed, and the trace amount of metal, residual soap and residual fat are removed in a maximum amount, and a part of the pigment is moderately removed.

(3)Deodorization

Deodorization of oil and fat not only removes odor substances in oil, but also improves the smoke point of oils and fats, improves the flavor of edible oils, and effectively improves the safety of oils and fats.

(4)Filteration

Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter, then enters into fine filter, in which clay and fixed impurities are blocked.

(5)Dewaxing processBleached sunflower seed oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization process, this process is controlled by the computer through the parameters preestablished, the computer controls temperature of circulating water in the frozen coil to command cooling speed of the oil,t hereby receive the best crystal result.

Our cooking oil process line could press many different raw materials, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Emballage et livraison

Toute exigence particulière d’expédition, veuillez nous en parler, nous vous aiderons à résoudre les problèmes. Si la quantité de marchandises à livrer est relativement faible, les marchandises seront emballées sous forme de caisses en bois d’exportation. Si les marchandises sont expédiées en grandes quantités, les marchandises seront directement chargées dans les conteneurs et coupées et renforcées pour éviter que les marchandises n’entrent en collision.

Entreprise

Zhengzhou Qi’E Grain&Oil Machine Co., Ltd est une entreprise à capital-actions de grande taille spécialisée dans la production d’équipements mécaniques d’huile comestible, de machines de fabrication d’huile de maïs et c’est également une entreprise de groupe intégrant la recherche scientifique, la fabrication et la vente en une seule. Nos machines de fabrication d’huile sont exportées vers plus de 30 pays et régions tels que le Gabon, le Congo, le Mali, l’Ukraine, le Sénégal, Abidjan, etc.

1. Plus de 30 ans d’expérience

2. Équipe de production de premier ordre

3. Produits de haute qualité

Nos clients

La production et les indicateurs économiques globaux sont à l’avant-garde de la même industrie, avec des produits vendus dans tout le pays et exportés vers plus de 40 pays, tels que le Gabon, le Mali, l’Ukraine, le Sénégal, Abidjan, le Kazakhstan, la Corée, le Bénin, le Sénégal, la Roumanie et la Serbie, etc.

Considérez la qualité comme la vie de l’entreprise, considérez le client comme Dieu, le bénéfice mutuel et la situation gagnant-gagnant avec le principe d’intégrité.

Coopération honnête, dévouée et sincère !