50tpd Sunflower Seeds Oil Squeezing Machine Manufacturer in Zimbabwe

- usage: SUNFLOWER OIL

- max capacity: 1000 kg/h

- weight: 15000 KG

- warranty: 1 Year

- oil type: Soybean Oil, sunflower seed oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 98%-100%

- voltage: 220V,380V or 440v

- dimension(l*w*h): 15*12*10m

- key selling points: Famous brand motor

- Raw materials suitable: Soybean,Sunflower,Sesame,Copra,Mustard,Peanut,Etc

- Machinery type: Screw Seed Oil Extraction Machine

- Residual oil in meal: 1%

- Function: sunflower oil plant

- solvent: n-hexane

- Feature: High productivity

- Application range: edible Oil Production

- Advantage: Energy Saving

- Machine Material: 304 Stainless Steel

- keyword: sunflower oil production line

- Selling Units: Single item

- Single package size: XX cm

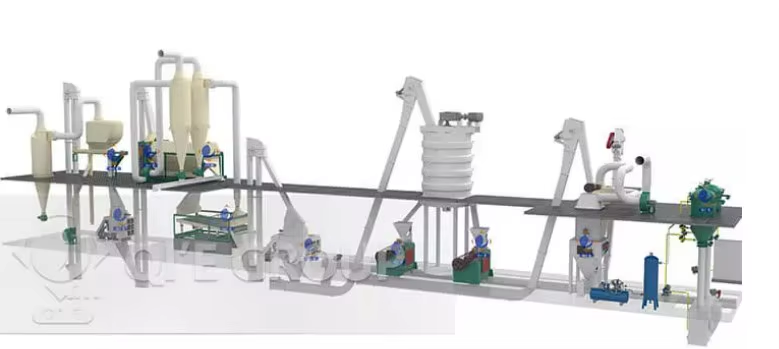

50tpd Sunflower Seeds Oil Squeezing Machine Manufacturer in Zimbabwe

We can provide full sunflower seeds soybean peanut cotton seed oil production line, includes press,extraction and refining equipment.

Production Capacity: 30-1000TPD

01. Machines used in pre-treatment of 50tpd Sunflower Seeds Oil Squeezing Machine Manufacturer in Zimbabwe

magnetic separator, cleaning sieve, stone removing machine, peeling and kernel separation equipment, embryo rolling machine, steaming and frying pan

02. Pressing of sunflower oil machine plant:

After pre-treatment, sunflower seeds will be transported into a sunflower oil press for squeezing to obtain sunflower oil.

03. Solvent Extraction of 50tpd Sunflower Seeds Oil Squeezing Machine Manufacturer in Zimbabwe

1. sunflower seeds cake → Solvent Extraction → Wet meal desolventizing → Cooling → Product meal packing

2. Solvent Extraction → Miscella → Filter → Negative pressure evaporation → Crude oil Solvent

3. Negative pressure evaporation → recovery

04. Refining of 50tpd Sunflower Seeds Oil Squeezing Machine Manufacturer in Zimbabwe

*Degumming: using hydration degumming to remove peptic impurities;

*Deacidification: using chemical or physical methods to remove free fatty acids;

*Decolorization: using the adsorption of white clay to remove the pigment in the oil and improve the color of the oil;

*Deodorization: using the difference in the volatility of oil and odor substances to remove odor substances;

*De-waxing: It mainly adopts freezing, crystallization or winterization crystallization to remove wax fat in oil by fractional distillation.

Degumming

Decolorization

Deodorization

Filteration

Dewaxing

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

2.Top production team

3.High quality products