Large Capacity Soybean Oil Processing Plant Complete Soybean Oil Extraction Line in Pakistan

- usage: Soybean oil production line

- max capacity: 1000tpd

- weight: 20000

- warranty: 1 Year

- oil type: Flax Seed Oil, Soybean Oil, Rap seed oil, SESAME OIL, Pinenut oil, sunflower seed oil, Peanut Oil, Coconut Oil

- type: Cold & Hot Pressing Machine

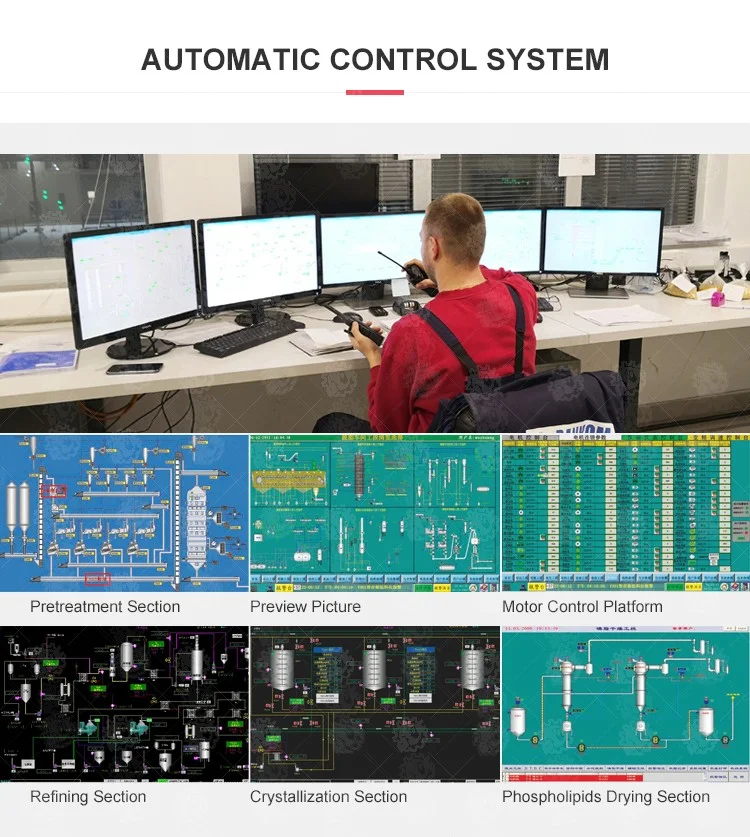

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- key selling points: High Productivity

- Product name: large capacity soybean oil processing plant

- Raw material: Soybean, sunflower, groundnut, peanut, sesame, etc.

- Keyword 1: soybean oil processing plant

- Keyword 2: edible oil refiner

- Factory visit: Welcome

- Certification: ISO9001:2008

- Advantage: High Oil Press Yield Rate

- Press type: Hot Cold Oil Press

- Final product: Edible Vegetable Oils

- Character: Professional Manufactuer

- Selling Units: Single item

- Single package size: XX cm

Large Capacity Soybean Oil Processing Plant Complete Soybean Oil Extraction Line in Pakistan

Complete soybean oil production line including raw material pretreatment, oil extraction and oil refining.

Section 1: Soybean pre-treatment process:Cleaning – Conditioning – Cracking and Dehulling – Flaking – Expanding and Cooling – Hulls Crushing – Aging and Pelleting

The main purpose of pretreatment is to remove impurities such as gravel, soil, and grass clippings in the raw materials. On the other hand, it is to change the shape and moisture of soybeans and prepare for soybean oil extraction.

Section 2 : Soybean oil extraction:Solvent– Extractor–Mixed oil — 1st and 2nd evaporation — Stripping tower — Crude oil

1.Extraction: The solvent enters material, and extracts oil inside the material under a certain level of temperature and pressure.

2.DTDC: It consists of seven layers. In the first three layers, the wet mash is heated by indirect steam. In the next two layers, stripping is carried out under the action of direct steam, the sixth layer is dried with hot air, and the seventh layer is cooled.

3.Evaporation: The difference between the boiling point of oil and the solvent is used to separate the solvent and the oil.

4.Stripper: The separated solvent can be dissolved in the selected paraffin or solvent and recycled.

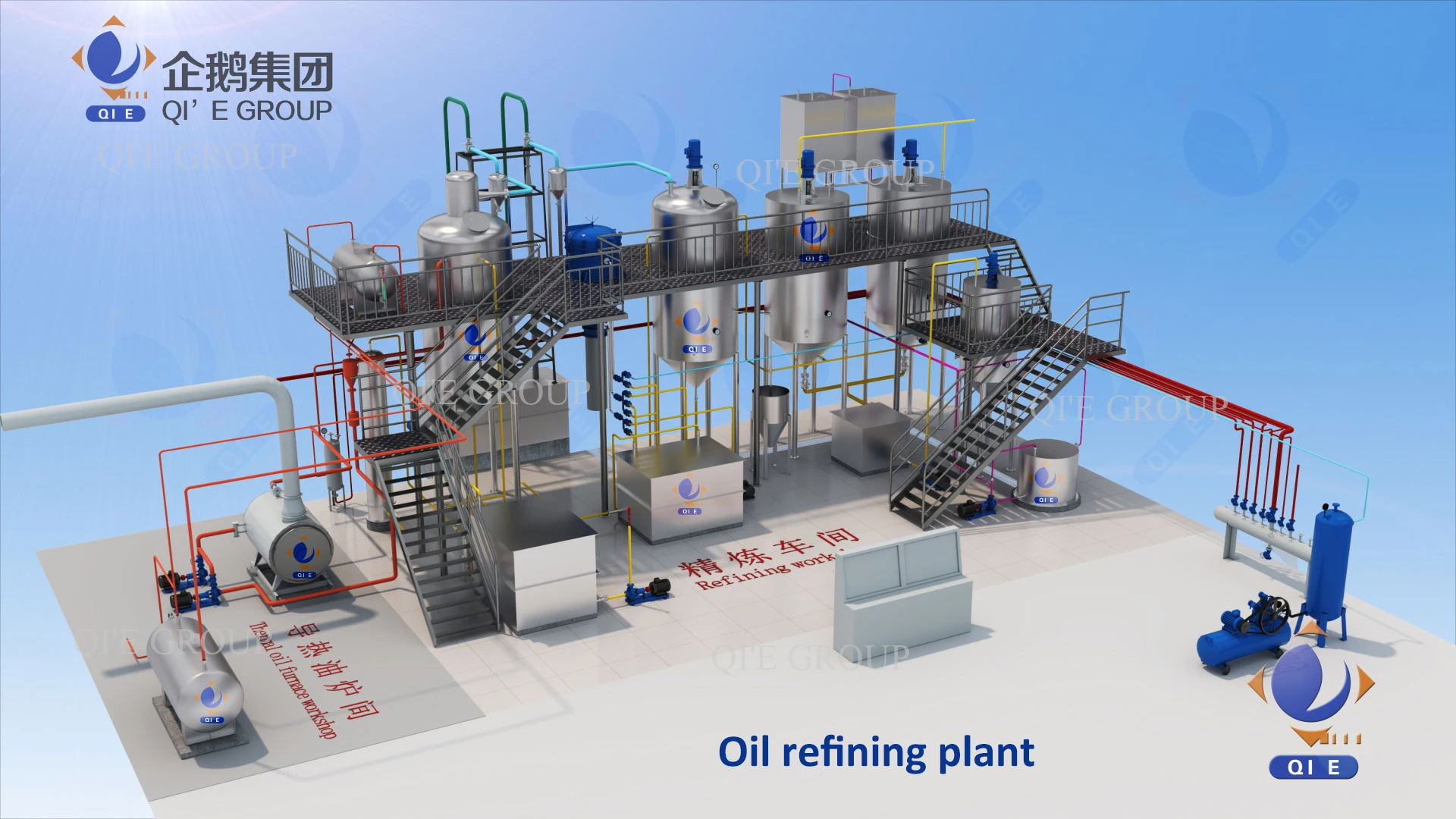

Section 3: Oil refining machine:crude oil – degumming & dephosphorization – deacidification – drying – decolorization – deodorization – defatting – dewaxing – finished oil.

Oil refining can remove mechanical impurities, solute fat impurities, pigments, moisture and other impurities in the oil, and then to produce pure high-quality edible oil.

| Usage | Soybean oil production line |

| Type | Cold & Hot Pressing Machine |

| Automatic Grade | Automatic |

| Place of Origin | China |

| Voltage | 220V/380V/440V |

| Oil type | Soybean Oil |

| Max Capacity | 3000tpd |

| Product name | Large Capacity Soybean Oil Processing Plant Complete Soybean Oil Extraction Line in Pakistan |

| Raw material | Soybean |

| Factory visit | welcome |

Our company have different machine suitable for all kinds of oil seeds, eg: sunflower seed, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Our company have different machine suitable for all kinds of oil seeds, eg: sunflower seed, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

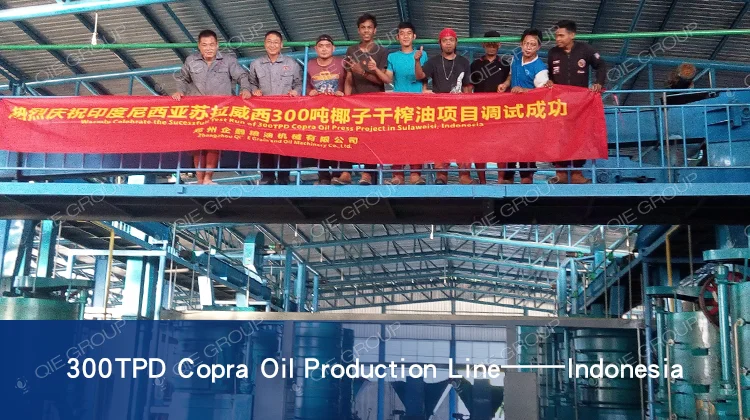

Customer Case

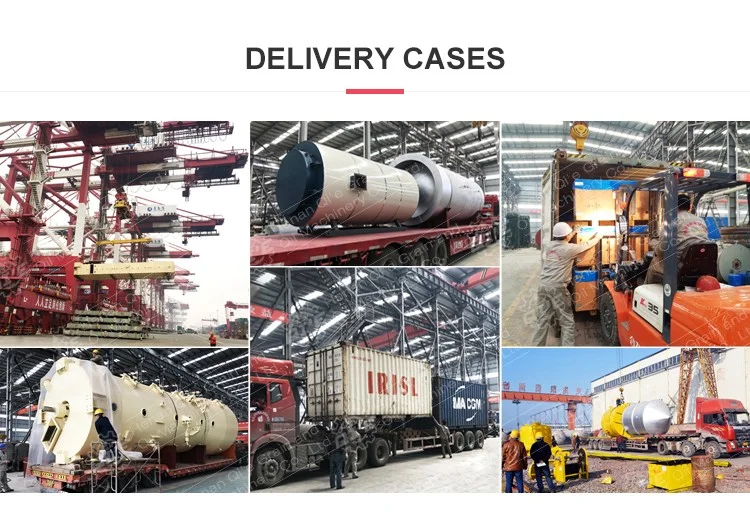

Packing & Delivery

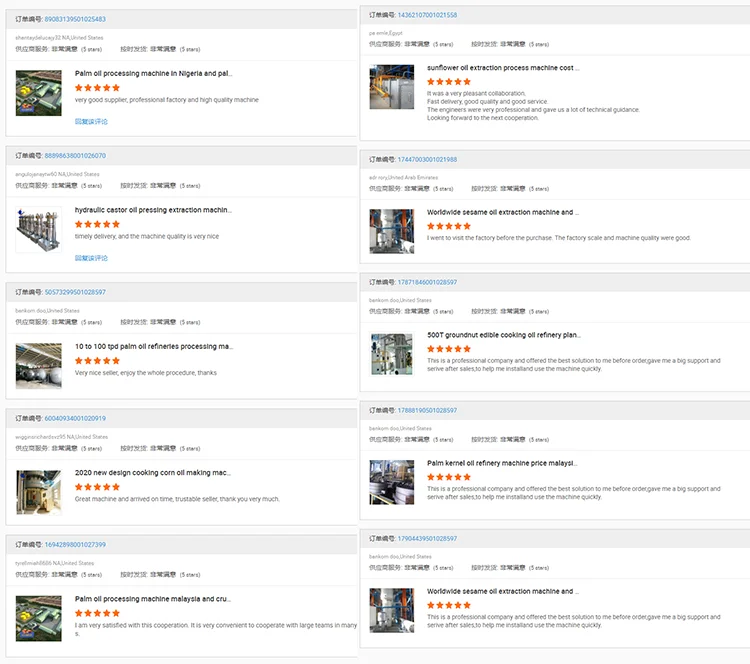

Customer Feedback

Company Profile

HENAN QIE Machinery Equipment CO.,LTD –Qie Group is a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Certifications

Our Service

Service before sale

1. 24 hours online. Your inquiry will be quickly replied by email. Also all questions with you can be solved by any online chatting tools.

2. Professionally and patiently introduction, details pictures and working video to show machine.

Service on sale

1. Installation: quality and quantity guaranteed; completion of hand over.

2. Acceptance: acceptance test; accepted deliverables.

3. Technical training: on-site installation and products training.

Service after sale

1. Technical service: long time technical service.

2. Accessories supplying: supplying spare parts with cost price.

3. Client review: call-back; regular return visit.

4. 24 hours online to solve any problem .