Castor Seed Oil Cold Hot Press Machine Castor Bean Oil Extraction Machine Plant in Nepal

- usage: Castor Oil

- max capacity: 2000tpd

- weight: 2000

- warranty: 1 Year

- oil type: Flax Seed Oil, Soybean Oil, SESAME OIL, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 85 Sets Monthly

- voltage: 380V~440V

- dimension(l*w*h): Based on capacity

- key selling points: High Productivity Edible Oil Project

- Product name: Castor seed oil machine

- Raw material: Sunflower, soybean, sesame, mustard and etc.

- Processing: batch-type or semicontinuous

- Electric consumption: 28Kwh/T Edible oil refinery line

- soften water: 150Kg/T Edible oil refinery line

- Phosphoric acid: 2~3 kg/T Edible oil refinery line

- Bleaching earth consumption: 3-5Kg/T Edible oil refinery line

- Refining rate: refining consumption 1%

- Waste bleaching earth oil content: 25% to 35 %

- Circulating water cooling water yield: 150M3/H

- Selling Units: Single item

- Single package size: XX cm

Castor Seed Oil Cold Hot Press Machine Castor Bean Oil Extraction Machine Plant in Nepal

A general term for a series of processes for removing solid impurities, free fatty acids, phospholipids, gums, waxes, pigments, odors, etc. contained in vegetable oils. Enhancing the nutritional value of edible oils has great benefits for human health.

Parameters of castor seed oil cold hot press machine castor bean oil extraction machine plant

| Steam consumption | 450KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Circulating water cooling water yield | 150m³/H |

| Bleaching earth consumption | 5~50Kg/T oil |

| Waste bleaching earth oil content | <35% |

| Deodorization loss consumption | ≤0.5% |

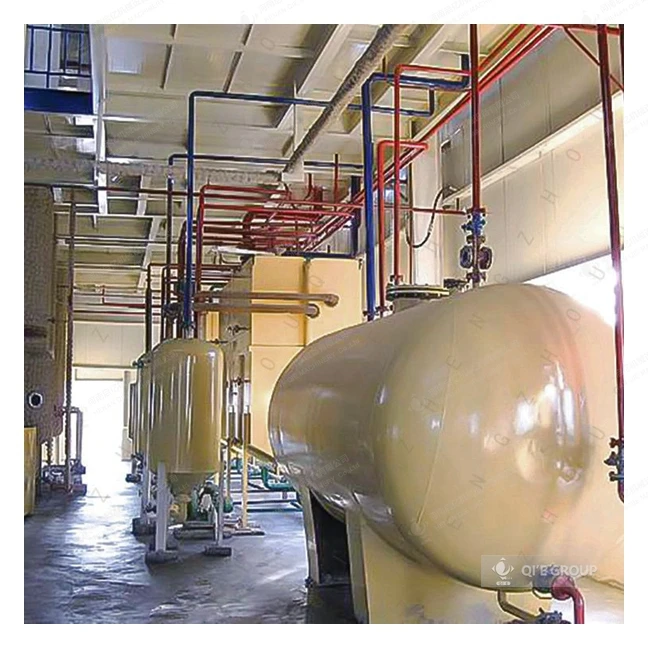

Main equipments of castor seed oil cold hot press machine castor bean oil extraction machine plant

Degumming: Thorugh hydration method, heating method, an acid addition method etc remove the Colloidal impurities.

Neutralization: By adding alkali, reaction with acid, a fatty acid salt (soap) and water are formed, and the soap adsorbs some impurities to precipitate and separate.

Bleaching: The adsorbent adsorbs the pigment and other impurities in the oil and fat, and removes the adsorbent and impurities through filtration to achieve the purpose of decolorization and purification of the oil.

Deodorizing Tank: Under vacuum and high temperature, through steam stripping to remove the odor-causing substance in the oil.

Degumming

Decolorization

Deodorization

Filteration

Dewaxing

The different technical process of castor seed oil cold hot press machine castor bean oil extraction machine plant

The complete edible oil refinery equipment includes batch refining, semi-continuous refining and continuous refining.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

2.Top production team

3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!