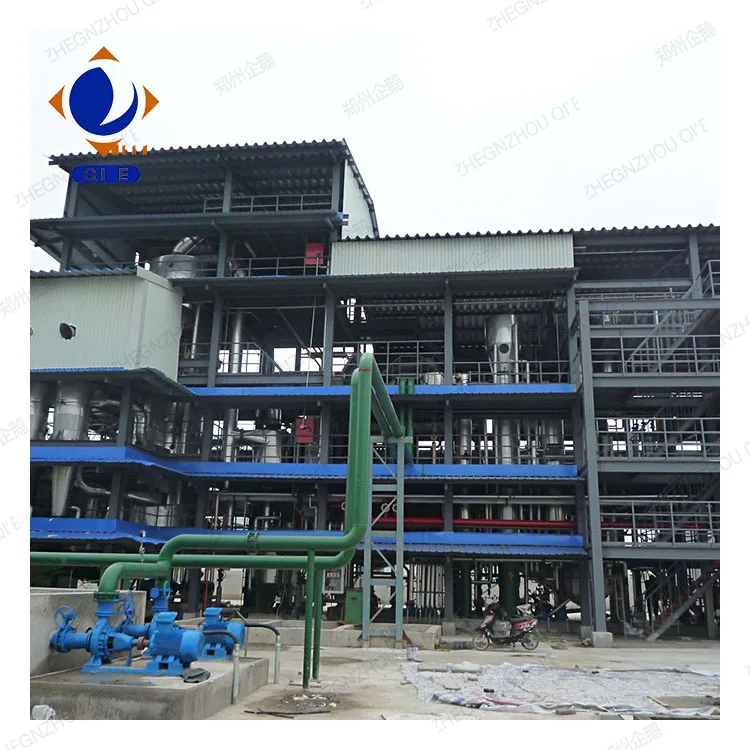

Usine de production d’huile de germe de maïs au Congo

- Utilisation : Prétraitement, extraction, raffinage

- Capacité maximale : 10-1000 tpd

- Poids : 1000

- Garantie : 1 an

- Type d'huile : Huile de maïs, huile de germe de maïs

- Type : Projet d'huile de maïs clé en main

- Qualité automatique : Automatique

- Capacité de production : 88 ensembles par mois

- Tension : 380 V ou 440 V

- Dimensions (L x l x H) : Selon la capacité

- Principaux arguments de vente : Projet d'huile de germe de maïs à haut niveau de sécurité

- Nom : Machine d'usine de traitement d'huile de germe de maïs

- Fonction : Fabrication d'huile comestible

- Application : Ligne de production d'huile

- Type d'extracteur : Extracteur Rotocel

- Utilisation : Usine de production d'huile de germe de maïs

- Capacité : Usine de production d'huile de germe de maïs

- Matériau de l'équipement : Acier inoxydable ou acier au carbone

- Matière première : Huile de maïs, tourteau de palme, graines de tournesol, etc.

- Système d'extraction : Système de grillage

- Utilisation : Machine de traitement d'huile de maïs

Corn Germ Oil Machine Plant Corn Germ Oil Processing Machine in Congo

A brief introduction to corn germ oil processing machine

1.The pretreatment process of corn germ oil processing machine

Nettoyage : Élimine la plupart des impuretés du matériau, telles que les pierres, la saleté, etc., pour préparer le prochain processus de concassage, améliorer l’efficacité du concassage et prolonger la durée de vie de la machine.

Concassage : Après le processus de concassage, le matériau est brisé en petits morceaux, ce qui améliore l’efficacité du matériau pressé.

Processus d’adoucissement : Augmente la teneur en humidité et la température du matériau, et augmente finalement le rendement final en huile du matériau.

Processus d’écaillage : le matériau est pressé en morceaux dans ce processus pour augmenter la quantité d’huile rejetée par le matériau.

Oil press: the treated oil enters the squeegee from the hopper.

Under the condition of high pressure, the embryo is continuously pushed inward by the screw press, and is pressed to finally produce oil.

| Residual oil in cake | ≤5% |

| Handling Capacité | 500kg-50tons/h |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Consommation de vapeur | ≤120Kg/T (0.8MPa) |

| Mechnical impurities | ≤ 0.3% (adjustable) |

| Moisture in crude oil | ≤ 0.2% (qualified detonated experiment |

2.The extraction process of corn germ oil processing machine

(1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Extraction→DTDC→Evaporation→Stripper→Crude oilExtraction:

The solvent enters the material and extracts the oil inside the material under a certain temperature and pressure.

DTDC: It consists of seven layers. in the first three layers, the wet mash is heated and heated by indirect steam to pre-dissolve and remove a large amount of solvent. in the next two layers, stripping is carried out under the action of direct steam, the sixth layer is dried with hot air, and the seventh layer is cooled.

Evaporation: The difference between the boiling point of the oil and the solvent is used to separate the solvent and the oil.

Stripper: The separated solvent can be dissolved in the selected paraffin or solvent and recovered.

The extraction operating principle of corn germ oil processing machine

(a) At a certain speed, the material is transported clockwise, and the solvent enters the material counterclockwise, so that the solvent and the material can be contacted to the greatest extent, and the oil yield is improved.

(b) in DTDC, in the evaporation stage, the solvent is evaporated as much as possible, and the solvent is recycled to recycle. Then in the stripping stage, the amount of solvent in the final oil is less than the local specified amount.

(c) The most important thing in the whole process is to control the temperature. Because the boiling point of the solvent and oil are different, so the temperature is controlled, then the quality of the obtained oil will be very good. Do the work of exhaust gas generated during the process of recycling and leaching to protect the environment.

Result of oil slovent extraction

| Moisture of extraction material | 5-8% |

| temperature of extraction material | 50-55°C |

| oil content of extraction material | 14-18% |

| thickness of extraction cake | less than 13mm |

| powder porosity of extraction material | less than 15% (30 mesh) |

| solvent | national standard No. 6 solvent oil |

| volume of supplement water | 1-2m/t raw material |

Introduction of corn germ oil processing machine Terme général désignant une série de procédés permettant d’éliminer les impuretés solides, les acides gras libres, les phospholipides, les gommes, les cires, les pigments, les odeurs, etc. contenus dans les huiles végétales. Améliorer la valeur nutritionnelle des huiles alimentaires présente de grands avantages pour la santé humaine.

The refining flow chart of corn germ oil processing machine

Parameters of oil refining machine

| Consommation de vapeur | 450KG/T oil |

| Consommation électrique | 28 kWh/t de pétrole |

| acide phosphorique | 2~3 kg/T d’huile |

| Rendement de l’eau de refroidissement par circulation d’eau | 150m³/H |

| Consommation de terre décolorante | 5~50Kg/T oil |

| Teneur en huile des déchets de terre décolorante | <35% |

| Perte de consommation de désodorisation | ≤0.5% |

The refining process of corn germ oil processing machine

1. Deacidification and degumming

This step is mainly to remove the excess acid in the grease. If the peptized impurities of the oil are not removed, the excessive emulsification will occur during the alkali refining process, so that the oil soap can not be separated well, affecting the refining and Oil quality. When decolorizing, the colloid will cover part of the active surface of the decolorizing agent, so that the decoloring efficiency is lowered, the temperature is higher when deodorizing, the colloid is carbonized, and the color of the grease is increased.

2. Decolorization

The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil. in this process, the oxide is completely removed, and the trace amount of metal, residual soap and residual fat are removed in a maximum amount, and a part of the pigment is moderately removed.

3. Deodorization

Deodorization of oil and fat not only removes odor substances in oil, but also improves the smoke point of oils and fats, improves the flavor of edible oils, and effectively improves the safety of oils and fats.

4. Filteration

Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter, then enters into fine filter, in which clay and fixed impurities are blocked.

5. Dewaxing process

Bleached sunflower seed oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization process, this process is controlled by the computer through the parameters preestablished, the computer controls temperature of circulating water in the frozen coil to comand cooling speed of the oil, thereby receive the best crystal result.

Emballage et livraison

The Advantages

(a)Taux d’huile résiduelle in the dry meal is low.

(b)Improving the quality of the oil.

(c)Low processing cost, high labor productivity.

(d)High automatic and labor saving.

And more other advantages please contact me now, we will provide profession program for you, and we accept custom according your requirements.

Entreprise

Zhengzhou Qi’E Grain&Oil Machine Co., Ltd est une entreprise à capital-actions de grande taille spécialisée dans la production d’équipements mécaniques d’huile comestible, de machines de fabrication d’huile de maïs et c’est également une entreprise de groupe intégrant la recherche scientifique, la fabrication et la vente en une seule. Nos machines de fabrication d’huile sont exportées vers plus de 30 pays et régions tels que le Gabon, le Congo, le Mali, l’Ukraine, le Sénégal, Abidjan, etc.

1. Plus de 30 ans d’expérience

2. Équipe de production de premier ordre

3. Produits de haute qualité

Nos clients

La production et les indicateurs économiques globaux sont à l’avant-garde de la même industrie, avec des produits vendus dans tout le pays et exportés vers plus de 40 pays, tels que le Gabon, le Mali, l’Ukraine, le Sénégal, Abidjan, le Kazakhstan, la Corée, le Bénin, le Sénégal, la Roumanie et la Serbie, etc.

Considérez la qualité comme la vie de l’entreprise, considérez le client comme Dieu, le bénéfice mutuel et la situation gagnant-gagnant avec le principe d’intégrité.

Coopération honnête, dévouée et sincère !