Fully Automatic Palm Oil Squeeze Machine Palm Oil Refinery Plant

- usage: Palm Oil Pressing, Refining

- max capacity: 2000tpd

- weight: 21930 KG

- warranty: 1 Year

- oil type: Crude Palm Oil, Refined Palm Oil

- type: Palm Oil Squeezing Machine

- automatic grade: Automatic

- production capacity: 98%-100%

- voltage: 220V/380V/440V

- dimension(l*w*h): 14*10*13m

- key selling points: High Productivity

- Product name: Machine to make palm oil

- Raw material: Palm kernel, Palm fruit, Crude palm oil

- Advantage: Energy Saving

- Application range: Palm oil extraction and refinery

- Material: 304 Stainless Steel

- Custom solution: Yes

- Used for: Pressing Palm Oil

- MOQ: 1 set

- Color and logo: custom

- Certification: CE/ISO9001/2000

- Selling Units: Single item

- Single package size: 5X2X3 cm

- Single gross weight: 0.500 kg

Fully Automatic Palm Oil Squeeze Machine Palm Oil Refinery Plant

QI’E is absolute authority on palm oil plant building, we had help many factories to building the fully-automated palm oil production lines and always received the praise and gratitude. We have model factories in many countries.

We have many professional engineers and we will provide you the most professional design services for free.

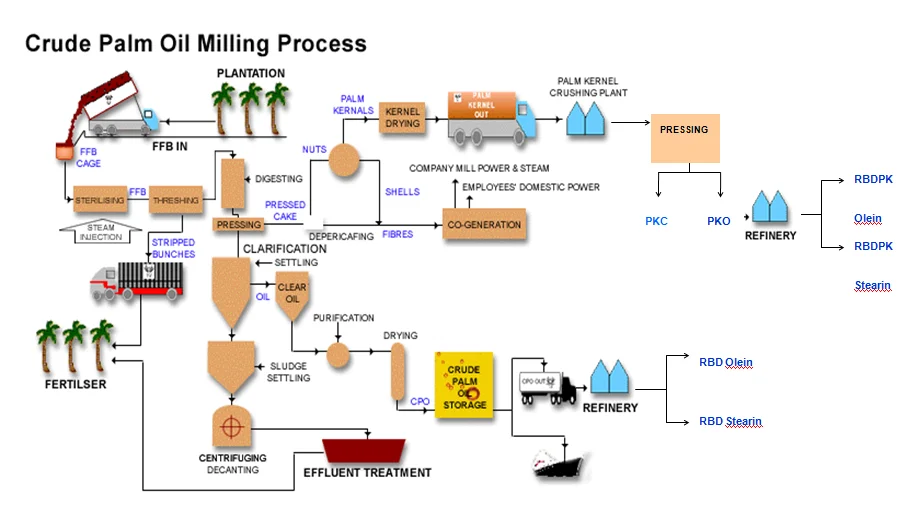

It mainly include following stations:RECEPTION STATION – STERILISER STATION – THRESHING STATION – PRESSING STATION – CLARIFICATION STATION – DEPERICARPING STATION – KERNEL RECOVERY STATION – BOILER HOUSE.

Mainly Procedure

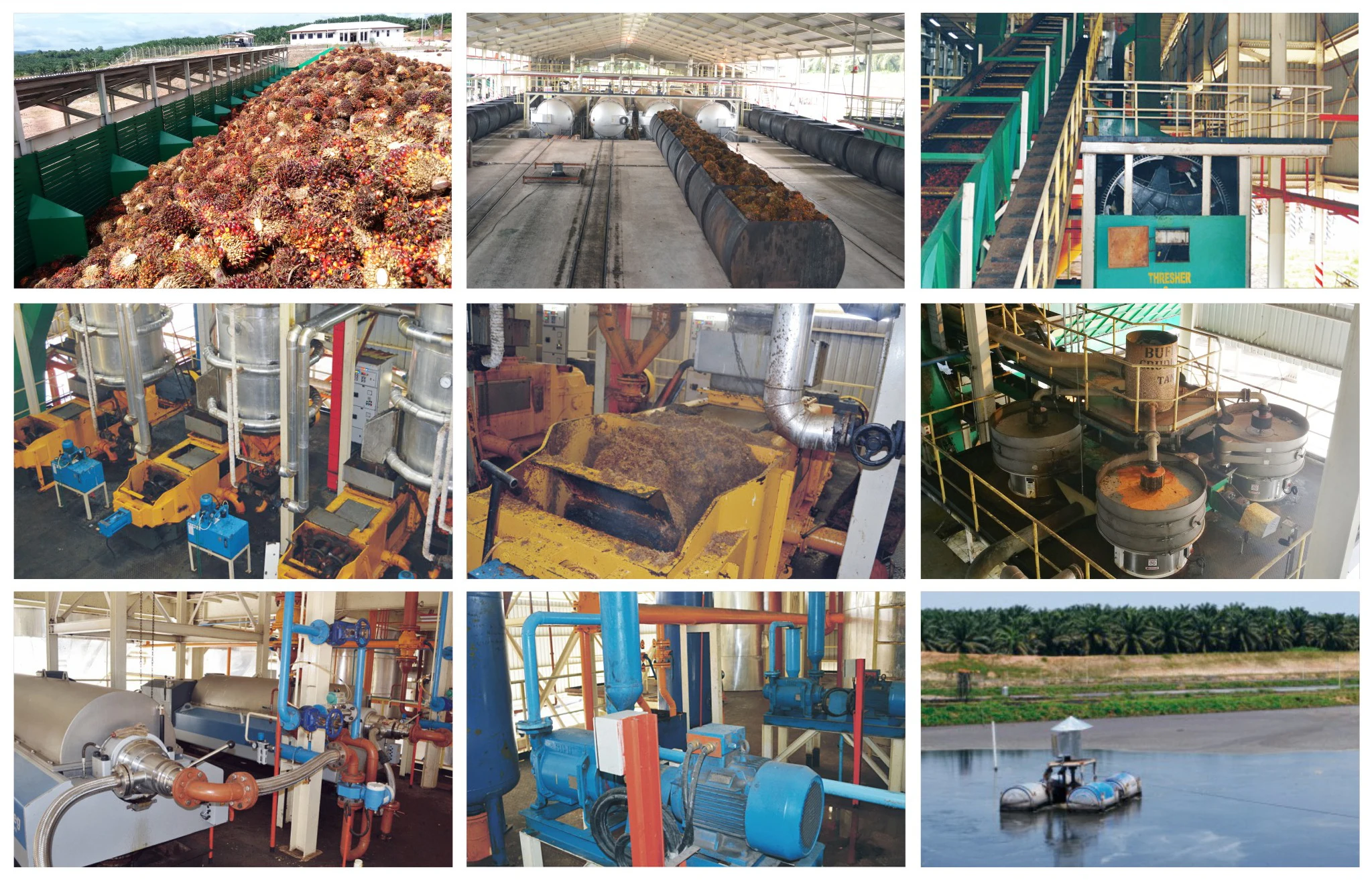

Reception station

Used for loading palm fruit brunch from plantation,transport to sterilizer,Reception station adopt steel structure and concrete structure.Save equipment cost and construction cost.Have hydraulic control system,hydraulic door open/off automatic achieve continuous operation.Reduce operator,operate more easily and improve work efficiency.

Sterilization station

The sterilizer works with direct steam, the steam can weaken the activity of the enzyme, prevent it getting rancid, ensure the good quality of the crude oil. At the same time, it is good for the following treshing processing. We have designed both horizontal and vertical sterilizer, for larger and smaller line.

Threshing station

The rotating of the drum in the tresher can separate the fruit from the bunch. The fruit will be conveyed to the digester through elevator, and the empty bunch will be conveyed to the outside part through scraper conveyor. The spindle adopts once forging technology, which can make the equipment more solider and durable. At the same time, we have already designed the non spindle tresher, which is driven by the link chain. It can save the producing cost in a large scale.

Digesting station

The digester is used to adjust the moisture and temperature of the fruit,finally it can increase the oil extraction rate. The digester adopts liquid level control system, which can distribute the material all by itself. To realize the automatic working. The presser adopts hydraulic control system to adjust the distance of different pressing worms, it is applicable to different kinds of palm fruits, and it can ensure the high oil extraction rate.

Pressing machine

The palm fruit oil yield increase by adjusting material moisture and temperature in digesting tank.digesting tank uses liquid level control, so material can distribute automatically and equipment runs fully automatically. Pressing machine uses hydraulic control system to adjust spacing between pressing bolts. So it can be suitable for various palm fruit species and guarantee the oil yield.

Clarification station

Using the latest technology, under the condition of ensuring the good quality of the oil, reduce the equipment cost as much as possible, reduce the loss of the oil, in the practical producing ,the new technology can make the loss of oil less than 1.3%.

The refining procedure of Crude Palm Oil Processing Plant Palm Kernel Oil Machine in Indonesia

There are 3 kinds of palm oil refining machine can be choosed:

1. Batch type palm oil refining machine capacity 1-20tpd;

2. Semi-continuous palm oil refining machine capacity 20-50tpd;

3. Full-continuous palm oil refining machine capacity over 50tpd.

Production Capacity: 50-1000TPD

Attention:

Palm oil mill process is quite different from other oil seeds processing, such as the soybean , peanut etc. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours.

Degumming

Degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

Bleaching

Bleaching process is mainly used to remove the color through adding white clay. You can add more if you want your oil color lighter.

Deacidification and Deodorization

The deacidification and deodorization of physical refining can be carried out together, the crude palm oil is processed under lowpressure and high temperature, the FFA will be stripped, and the smell and color will be removed.

Packing & Delivery

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

2.Top production team

3.High quality products

Our Service

Pre-sale services

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

After-sale services

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipment;

3) Training the first-line operators on site;4)Supplying spare parts with cost.

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!