Palm Oil Plant Palm Oil Processing Line in Cameroon

- usage: palm oil plant

- max capacity: 10-1000TPD

- weight: 10000 KG

- warranty: 1 years

- oil type: Palm Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- dimension(l*w*h): 48m*12M*15M(10-1000TPD)

- key selling points: Energy saving

- Product name: Palm and palm Kernel Oil Extraction Machine

- Keyword: Palm oil processing line

- Raw material: Palm Kernel/plam fruit

- Machine Material: Steel,carbon steel

- Acid value: Less than 1.0mg koh/g

- Residual oil in meal: Less than 1%

- Indine value: 44-46 gl/ 100g

- Feature: High Oil Yield Efficiency

- heating method: Steam heating

- Function: Making Edible Oil

- Packaging Details: For palm oil processing line: Standard international bubble film in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

- Supply Ability

- Supply Ability: 300 Set/Sets per Month palm oil processing line

If your are planning to setting up a palm oil production plant in Cameroon you are in the right place! We are a senior palm oil prodcution plant manufacturer in Asia. We are expert in palm oil processing line for both small, medium and large prodcution plant, with rich experience in palm oil plant desiging, equipment manufacturing, factory installation and oil mill commissioning.

Actually, Cameroon has rich oil palm sources, it is definitely profitable to set up palm fruit or palm kernel oil mill plant in Cameroon. However, the development of local palm oil production is restricted due to the lack of advanced oil processing technology. So, we came to there get an in-depth understanding of the situation and needs of local palm oil production investors and businessmen. And to offer more opportunities for local investor to expand and improved their oil processing technology.

Main Machinery for Making Palm Oil: Steriliser, digester, stripper machine, screw press, nut/fiber separator and so on.

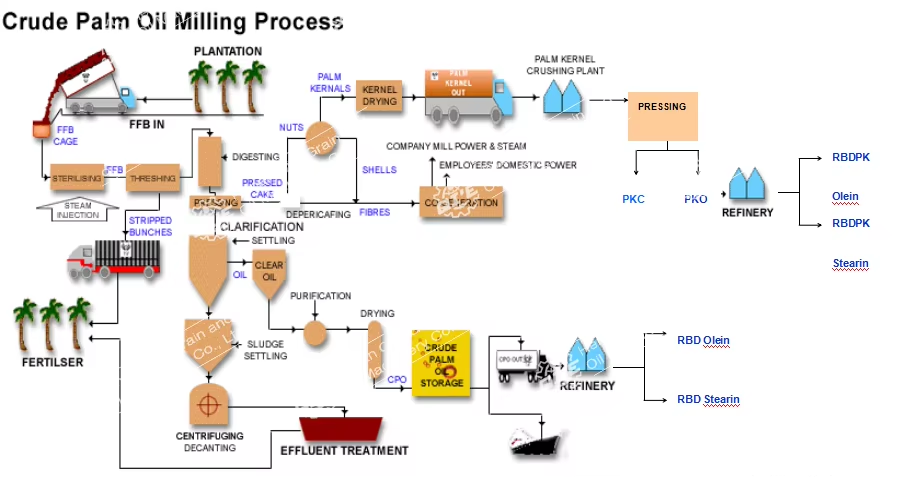

The manufacture of crude palm oil involves a series of processes starting with harvesting fresh fruit bunches from the plantations and ending with crude palm oil storage. Through sterilizing, threshing, mashing and expelling, crude palm oil will be pressed out in palm oil pressing machine (screw oil press). Each station of palm oil mill uses different methods and machines. After purifying and refining, the refined palm oil can be exported as a popular kind of healthy and edible oil. Browse through the details of palm oil manufacturing in the following:

Sterilizing Station

The disinfection process utilizes steam or water to sterilize the fresh palm fruits. This process likewise stops enzymatic responses that prompt oxidation and upsets the cells which are found in the mesocarp, so that to improve the oil extraction efficiency and final oil product quality.

Threshing Station

The fruitlets are separated from the whole bunches by use of stripper machine. Threshing is generally mechanical in large palm oil mill by use of thresher, which rotates or vibrates to remove the fruits from the bunch.

Digesting Station

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Oil Pressing Station

The pulp is then pressed, which bursts the oil-containing cells, releasing the palm oil. There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

Palm Oil Clarification Station

The purpose of clarification in palm oil manufacturing process is to remove impurities. The final crude palm oil will be storage in bulk in a tank.

Palm kernel recoveyor

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

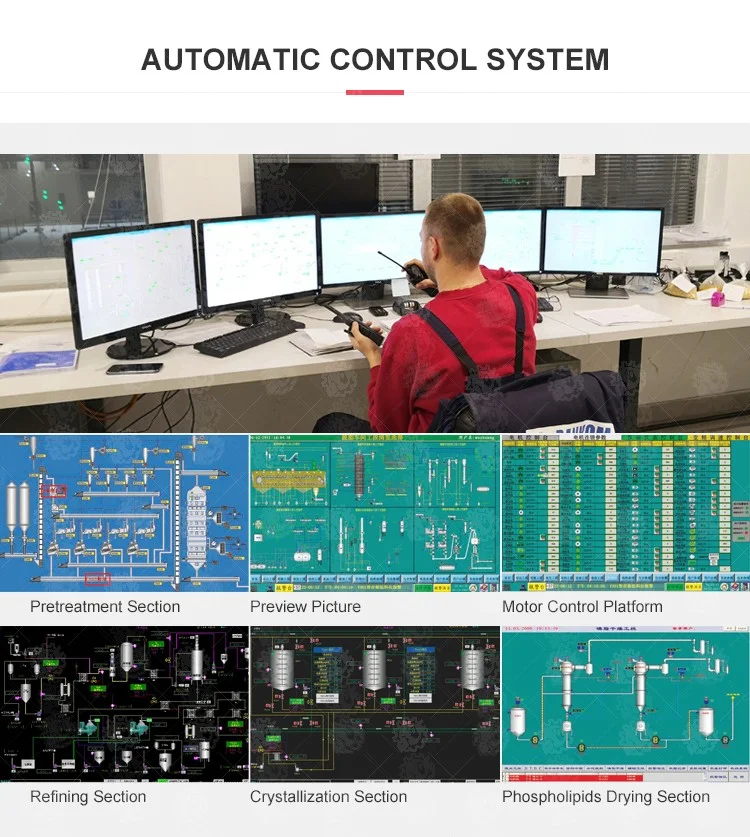

Features of palm oil processing machines production line:1 Compact and strong structure, and easy operation. 2 The automatic control system which can adjust barrel pressure. 3 High oil pressing efficiency, and residual oil in cake is less than 8%. 4 Low crushing efficiency for palm nut. 5 Invest is small, quick gains.

| Crude Palm Oil product scheme | ||

| crude oil moisture content | ≤0.1-0.2% | |

| Impurity content of crude oil | ≤0.2% | |

| Palm kernel moisture | ≤ 8% | |

| Husk content of palm kernel | ≤2.0% | |

Palm Oil refining: crude oil – degumming & dephosphorization – deacidification – drying – decolorization – deodorization – defatting – dewaxing – finished oil.

Oil refining can remove mechanical impurities, solute fat impurities, pigments, moisture and other impurities in the oil, and then to produce pure high-quality edible oil.

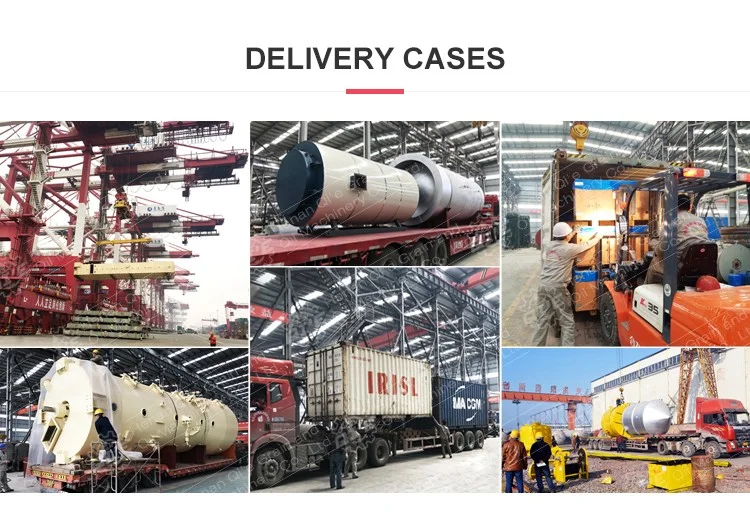

Packing & Delivery

Company Profile

HENAN QIE MACHINERY CO.,LTD — Qie Group is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.