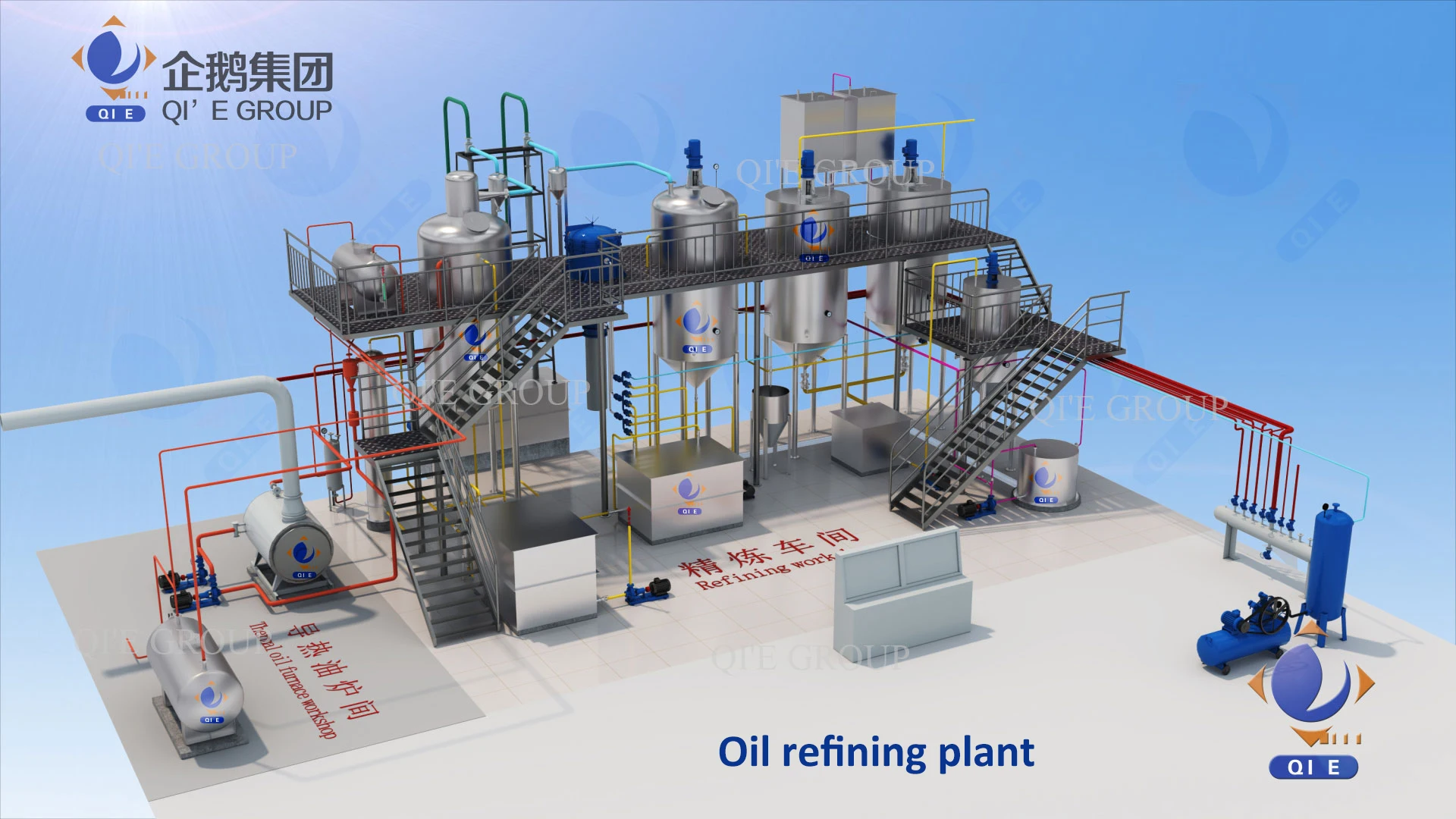

Physical Crude Palm Oil Refinery Equipment Palm Oil Degumming Machine in Colombia

- usage: Palm oil refining

- max capacity: 2000tpd

- weight: 1800 KG

- warranty: 1 Year

- oil type: Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, SESAME OIL, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

- type: High Productivity Palm Oil Project

- automatic grade: Automatic

- production capacity: 100 Sets Monthly

- voltage: 380V-440V

- dimension(l*w*h): Depends On Capacity

- key selling points: Multi-functional Palm Oil Plant

- Name: Physical Crude Palm Oil Refinery Equipment Palm Oil Degumming Machine in Colombia

- Function: Oil Refining

- Advantage: Energy Saving

- Product name: Vegetable Oil Refining

- Material: Stainless steel

- Application: Crude Oil Refining edible oil refinery project

- Color: Clients' Requirements edible oil refinery project

- Warranty: 12 Months edible oil refinery project

- Certificate: CE

- After Warranty Service: Professional Engineer Team

- Selling Units: Single item

- Single package size: XX cm

Physical Crude Palm Oil Refinery Equipment Palm Oil Degumming Machine in Colombia

crude oil → degumming&dephosphorization → deacidification → drying → decolorization → deodorization → defatting → dewaxing → finished oil.

(1)Deacidification and degumming

This step is mainly to remove the excess acid in the grease. If the peptized impurities of the oil are not removed, the excessive emulsification will occur during the alkali refining process, so that the oil soap can not be separated well, affecting the refining and Oil quality.

(2)Decolorization

The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil. In this process, the oxide is completely removed, and the trace amount of metal, residual soap and residual fat are removed in a maximum amount, and a part of the pigment is moderately removed.

(3)Deodorization

Deodorization of oil and fat not only removes odor substances in oil, but also improves the smoke point of oils and fats, improves the flavor of edible oils, and effectively improves the safety of oils and fats.

(4)Filteration

Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter, then enters into fine filter, in which clay and fixed impurities are blocked.

(5)Dewaxing processBleached sunflower seed oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization proces,this process is controlled by the computer through the parameters preestablished,the computer controls temperature of circulating water in the frozen coil to comand cooling speed of the oil,thereby receive the best crystal result.

QI’E Palm Project Cases

We can also provide turn-key project for palm oil machine

Main service of palm oil processing machine:

1TPH palm oil press project equipment manufacture,installation and Turnkey project;

2-10TPH palm oil press project equipment manufacture,installation and Turnkey project;

15-30TPH palm oil press project equipment manufacture,installation and Turnkey project;

40-100TPH palm oilt bunch press project equipment manufacture,installation and Turnkey project

;5-1000T/D palm oil refinery project production;

5-1000T/D palm oil fractionation project production;

Palm oil mill equipment re-modelling and maintenance;

Equipment spare part supply;

Palm Fruit Pressing Project in Indonesia

Palm Fruit Pressing Project in Indonesia Palm Oil Production Project in Cote d’Ivoire

Palm Oil Production Project in Cote d’Ivoire Palm Oil and Soybean Oil Refining in Egypt

Palm Oil and Soybean Oil Refining in Egypt Palm Oil Production Project in Thailand

Palm Oil Production Project in Thailand Palm Oil Refining Project in Mexico

Palm Oil Refining Project in Mexico Multi-Material Press&Refining in Burundi

Multi-Material Press&Refining in Burundi Palm Oil Refining&Fractionation in Peru

Palm Oil Refining&Fractionation in Peru Palm Oil Fractionation in Philippines

Palm Oil Fractionation in Philippines

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

2.Top production team

3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!