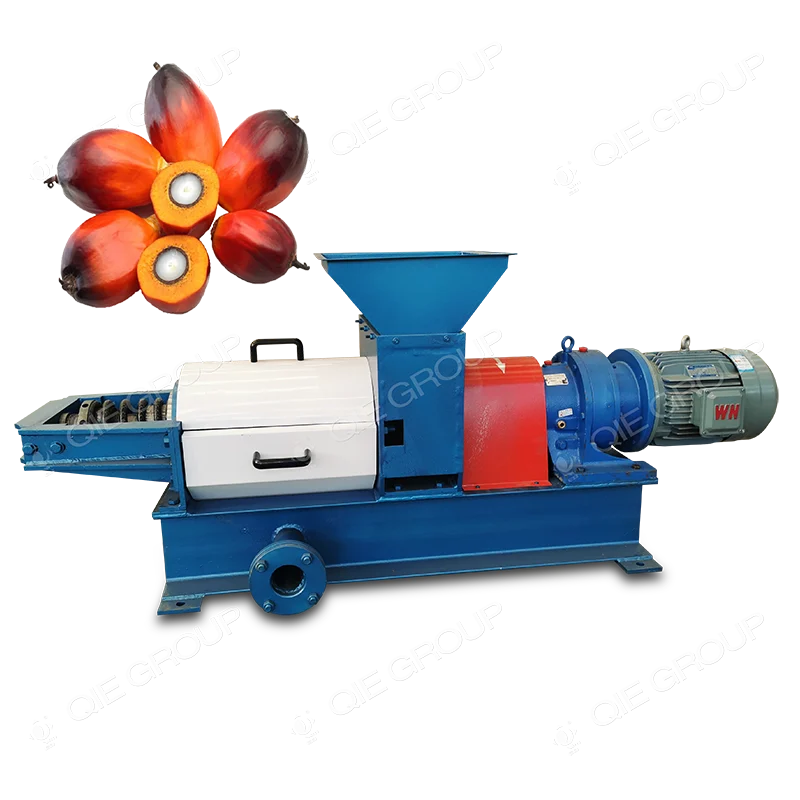

Small Palm Oil Fractionation Plant Red Palm Oil Refinery Machine in Nigeria

- usage: Oil fractionation machine

- max capacity: 5-100tpd

- weight: 1500 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: Palm oil fractionation machine

- automatic grade: Automatic

- voltage: 220V/380V/440V

- key selling points: Energy saving

- Product name: Crude palm oil fractionation machine

- Raw material: Crude palm oil

- Keyword 1: Palm oil fractionation machine

- Machine Material: Stainless Steel Oil Refining Machine

- Advantage: High Oilput

- Certification: CE/ISO9001/2000

- Oil rate: 96%-98%

- Processing Types: Physical Refinery

- Color: Customers' Requirements

- Output: 450kg/h

- Packaging Details: For palm oil fractionation machine: Standard international wooden boxes in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 200.000 kg

- Supply Ability

- Supply Ability: 300 Set/Sets per Month palm oil fractionation machine

Process: crystallization and separation.Cooling palm oil to crystallize, then separate crystal from oil to get solid fat and liquid oil. Adopt this technology, we can get palm oil with different melting points, like 33℃, 24℃, 18℃, 14 ℃,12℃,10℃,8℃,etc.Equipment: crystal jar, water-cooled screw chillers, membrane filter press

Palm oil fractionation plant: palm oil fractionation plant is used to process RBD palm oil (you get from palm oil refinery plant). Mainly include input RBD Palm Oil–Heating Melting (broken crystal)–Crystallizing—Filtering-output RBD palm OLein &RBD palm Stearin

Palm oil fractionation process flow:

① Dry fractionation process: Palm oil → Heating → Cooling and crystallization → Filtering → Olein and stearin

② Solvent fractionation process: Palm oil → solvent dilution → cooling crystallization → separation → solventevaporation → Olein and stearin

③ Surface active agent fractionation process: Palm oil → Palm kernel softener diluted palm kerneloil → Freezing → Moisturizing stearin crystals → Centrifuge separation → Washing → Drying → Olein and stearin

Specification

| Parameters | Method | Specification (CP10) | Specification (CP8) | Specification (CP6) |

| Slip melting point (°C) | AOCS Cc3-25(1989) | 24 °C Max | 20 °C Max | 18 °C Max |

| Iodine Value (wijs) | AOCS 16-87 (1992) | 56 min | 57 min | 60 min |

| Cloud point | 12 | 10 | 8 | 6 |

| Free fatty acids (%, As Palmitic) | AOCS 5a-40 (1989) | 0.1 Pct max | 0.1 Pct max | 0.1 Pct max |

| Moisture & Impurities | MPOGC Test Methods | 0.1 Pct max | 0.1 Pct max | 0.1 Pct max |

| Color (5.14″ Lovibond Cell) | BS 684 Section 1.14:1987 | 3 Red max | 3 Red max | 3 Red max |

Customer Case

Small crude palm oil fractionation plant for palm oil refinery machine workshop under construction

Customer Feedback

Customer Photos

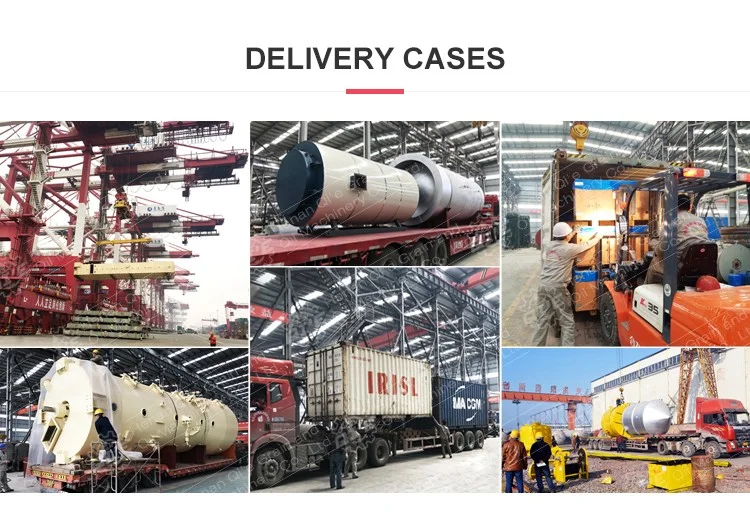

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems. If the amount of goods to be delivered is relatively small, the goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company Profile

HENAN QIE MACHINERY CO.,LTD is a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!