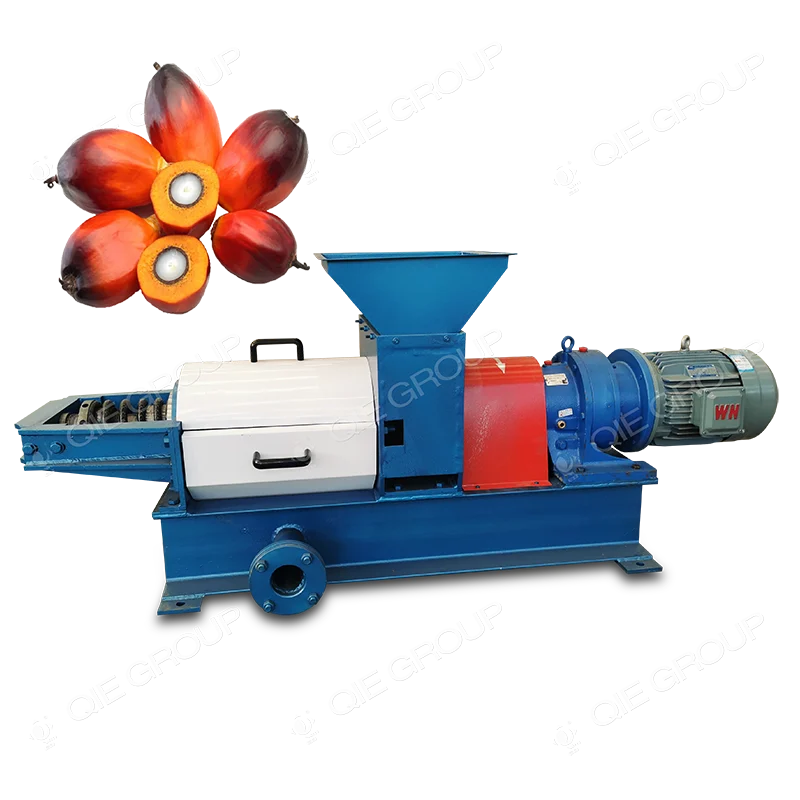

Small Scale Palm Kernel Oil Processing Machine Plant in Abidjan

- usage: palm oil mill

- max capacity: 10-1000TPD

- weight: 10000

- warranty: 2 years

- oil type: Palm Oil

- type: Cold & Hot Pressing Machine

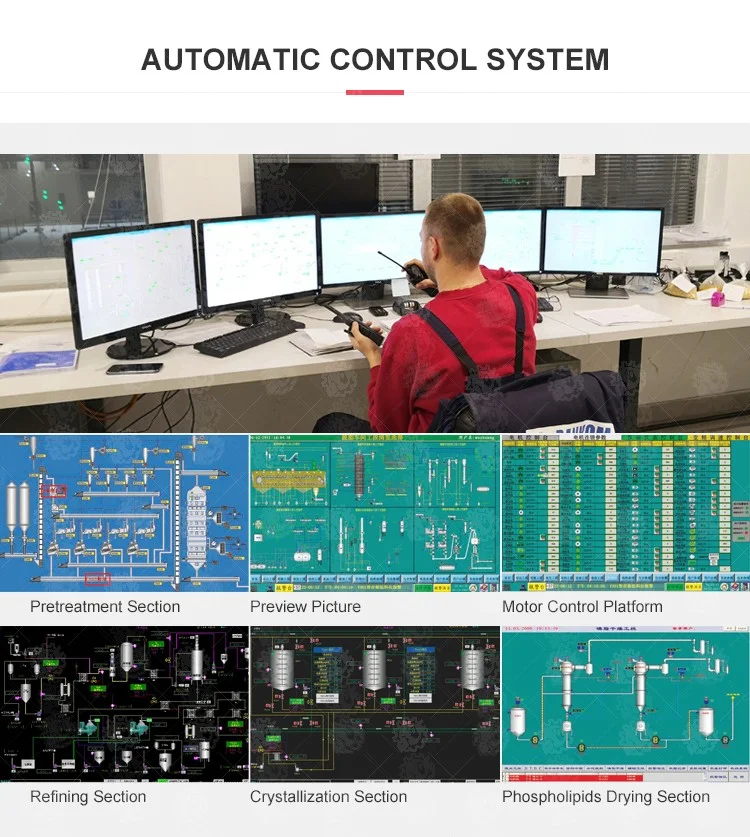

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- dimension(l*w*h): 48m*12M*15M(10-1000TPD)

- key selling points: Energy saving

- Raw material: Palm Kernel/plam fruit

- Machine Material: steel,carbon steel

- Acid value: less than 1.0mg koh/g

- Residual oil in meal: less than 1%

- Indine value: 44-46 gl/ 100g

- heating method: steam heating

- Feature: High Oil Yield Efficiency

- installation: our engineer will come for field installation

- Product name: palm oil milling machine

- Keyword: palm oil mill

- Selling Units: Single item

- Single package size: XX cm

Small scale complete palm oil mill line palm kernel oil processing machine plant with low cost

Our company is specialized in palm oil extraction machine, we can provide the palm oil extraction machine from 10 ton to 3000 tons per day capacity.

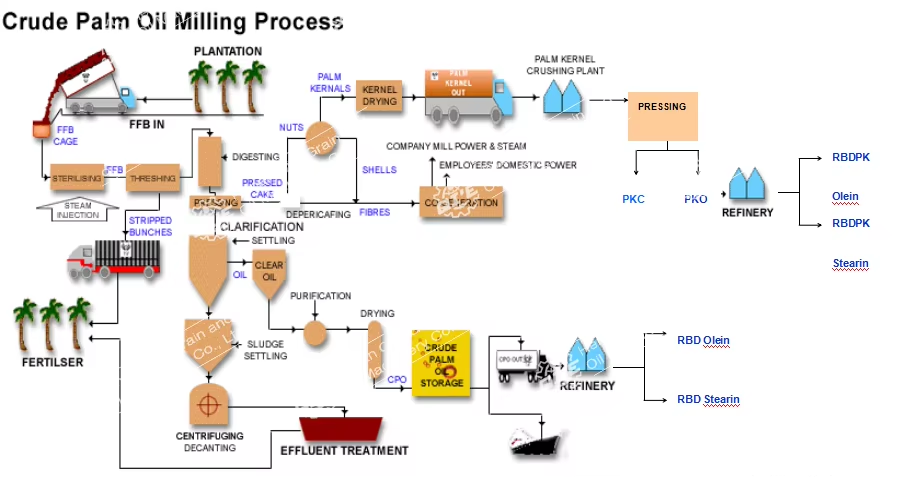

Technology of Small scale complete palm oil mill line palm kernel oil processing machine plant with low cost:Diesel Generator→ Steam Turbine→ Reception Station→ Palm Oil Plant Sterilizing Station→ Thresher→ Press Station→ Pressing station→Screen Filter→ Decanter Centrifuge→Vacuum Dryer→ Sewage Treatment

Diesel generator

Diesel generator Steam turbine

Steam turbine

Reception Station

Reception Station Sterilizing station

Sterilizing station

Thresher

Thresher Press Station

Press Station

Pressing station

Pressing station Screen filter

Screen filter

Decanter Centrifuge

Decanter Centrifuge Vacuum dryer

Vacuum dryer Sewage treatment

Sewage treatment

After transport the FFB to palm oil mill, the fruits will go to sterilizer by conveyor or palm fruit cage. After separating palm fruits and palm bunch by thresher, Pam fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel. After pressing, we can get palm cake and palm nut. Pam nuts will be conveyed to palm recovery system to get palm kernels, fiber and palm shell. Palm cake will be conveyed to boiler room as fuel. After filtering, centrifuging, vacuum drying, we can get crude palm oi (CPO), the CPO can be sold directly or used for further processing. The sewage from all the plant will be processed by sewage treatment to reach discharge standard. Sludge can be used for fertilizer in palm plantation. All the process cycle features with short operation cycle, high automaticity, energy conservation and environmental protection.

Features of small scale complete palm oil mill line palm kernel oil processing machine plant with low cost:1 Compact and strong structure, and easy operation. 2 The automatic control system which can adjust barrel pressure. 3 High oil pressing efficiency, and residual oil in cake is less than 8%. 4 Low crushing efficiency for palm nut. 5 Invest is small, quick gains.

| Crude Palm Oil product scheme | ||

| crude oil moisture content | ≤0.1-0.2% | |

| Impurity content of crude oil | ≤0.2% | |

| Palm kernel moisture | ≤ 8% | |

| Husk content of palm kernel | ≤2.0% | |

Palm Oil refining: crude oil – degumming&dephosphorization – deacidification – drying – decolorization – deodorization – defatting – dewaxing – finished oil.

Oil refining can remove mechanical impurities, solute fat impurities, pigments, moisture and other impurities in the oil, and then to produce pure high-quality edible oil.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Overseas Cooking Oil Production Line

| 10-500T/H oil material first cleaning, drying and storage section turnkey project. | 30-1000T/D oil continuous grade one or two physical (chemical) refining production line. |

| 20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project. | 10-200T/D Fatty acid esterification production cooking oil production line. |

| 1tph-120tph Palm Fruit Processing Line and Palm Kernel Processing Line. | 250TDPshea nut pressing,100TDP oil refining and oil fractionation Nigeria equipment. |

| 300TPD soybean pre-treatment and solvent extraction plant and oil refinery egypt plant. | 50TDPpalm oil refinery and fractionation plant and oil filling machine ghana. |

| 300TDP cotton seed pretreatment,solvent extraction and oil refining equipment kazakhstan. | Two sets 50TPD oil refining production line pakistan. |

Company Profile

HENAN QIE MACHINERY CO.,LTD is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.

Customer Photos

FAQ

1. Q: Which kind of materials can be process? A: All kinds of oil seeds. For example of common oil material:soybean, rice bran, corn germ, cottonseeds, peanut, sunflower, rapeseed, palm fruit etc. from the pre-treatment, pressing, solvent extraction to refining plant. 2. Q: What’s the production capacity can you process?A: 3-5000 tons per day. We can manufacture as customized order. 3.Q: How long is your guarantee ?A: One Year guarantee. We shall supply free exchange for spare parts. After this period, we shall charge at low cost to keep after service. You will be welcome to contact us with any problem might occurred. 4.Q: How is the quality of your products ? A : Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery. 5.Q:Can you install the machine in local place? A: We will send our engineers tolocal place to help installing the machine and provide technical guidance. 6.Q: What’s the payment terms? A:T/T,Trade Assurance, L/C, Cash etc.