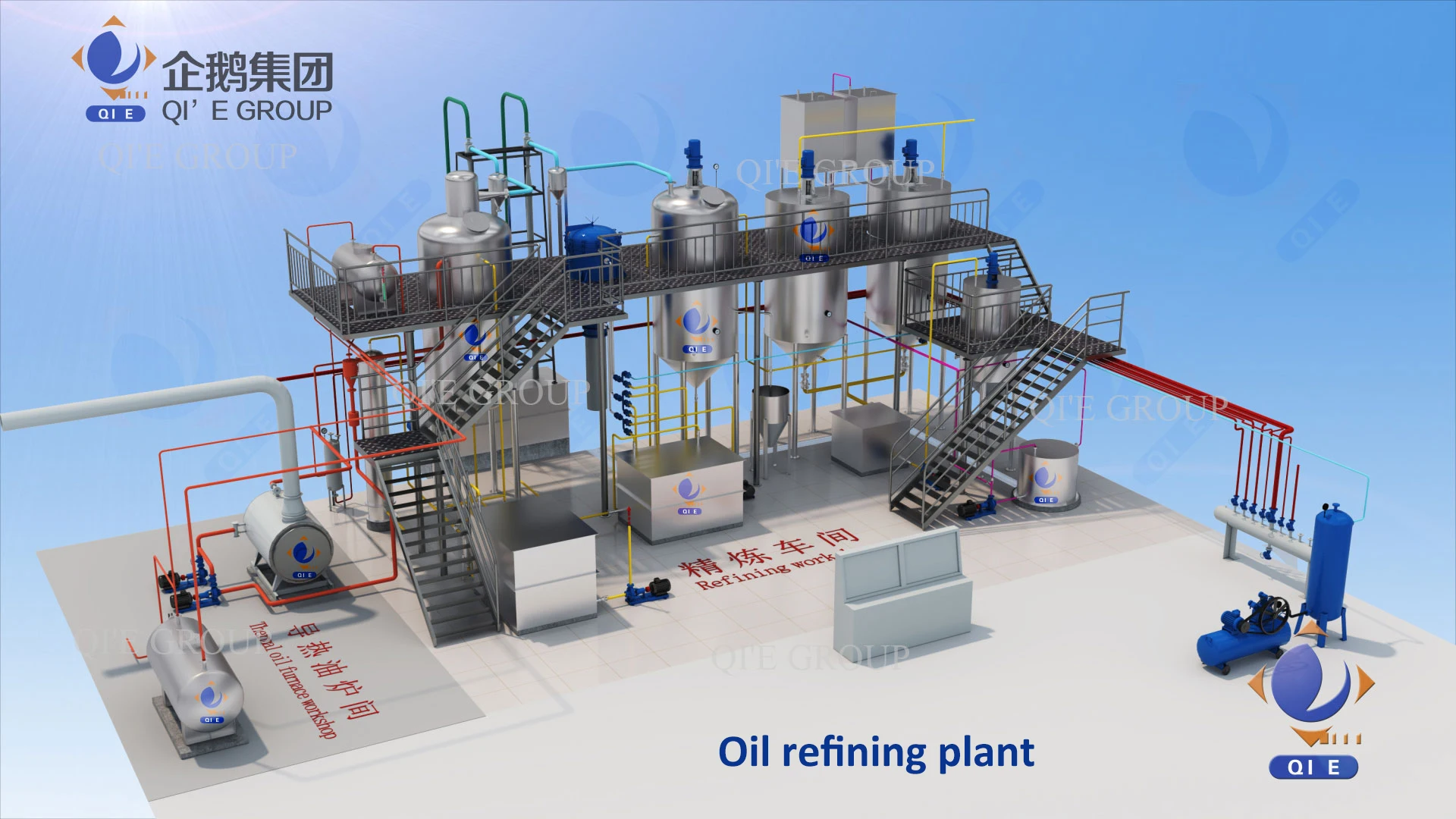

Small Scale Sunflower Cotton Seed Oil Refining Palm Oil Refinery Machine in Lesotho

- usage: Cooking oil refining

- max capacity: 1000tpd

- weight: 12000 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: Cooking oil refining machine

- automatic grade: Automatic

- production capacity: 85 Sets Monthly

- voltage: 380V,or other

- dimension(l*w*h): Depends on the capacity

- key selling points: Long Service Life Edible Oil Project

- Product Name: sunflower cotton seed cooking oil refining palm oil refinery machine

- Color: Depend on Requirements for Oil Refinery Equipment

- Electric Consumption: 28kwh/T Ooil

- Use: Cooking Oil Refinery Equipment

- Capacity: Based on Requirements for Oil Refinery Equipment

- Steam Consumption: 450kg/T Oil

- Deodorization Loss Consumption: ≤0.5%

- Bleaching Earth Consumption: 5~50Kg/T Oil

- Condition: New Oil Refinery Equipment

- Certification: BV, ISO9001, CE, etc.

- Selling Units: Single item

- Single package size: XX cm

Small Scale Sunflower Cotton Seed Cooking Oil Refining Palm Oil Refinery Machine in Lesotho

For Increasing demand of improving oil quality from the oil shop, it can realize the Degumming deacidification decolorization oil after refining plant can reach National Level 2 standard, it has been welcomed by clients all over the world.

The process of palm oil refining process

1.Degumming Section: Some impurity, such as Phospholipid, gum, and protein, can be oil when there is no water, but once there is water in oil, these impurities can be dissolved into water. So, in the degumming section, we use the hot water to wash crude oil.

2.Neutralizing Section: Crude oil contains much free fatty acid, which is harmful to health. Free fatty acid can have the reaction with caustic soda, during the reaction, it can be saponified and becomes soapstock Then small soapstock pellets will sink and becomes sediment and be pumped out. After neutralizing most of the free fatty acid will be removed out.

3.Decolorization Section: Most of the crude oil has deep color because of the pigments, such as carotene, xanthophyll, etc. We use bleaching earth to remove pigments because bleaching earth has strong adsorption capacity. Then pump oil into plate filter to remove bleaching earth then pigment also will be removed out along with bleaching earth, then oil will be clean and transparent.

4.Deodorizing Section: Pure oil has no smell, but different crude oil has their special smell because of some volatile matters, for example, the oxide for ketones, aldehydes, hydrocarbons. In the deodorizing section, we deliver steam into oil continuously and make sure steam and oil fully contacted under high temperature and pressure, then volatile matters can be removed out along with the steam.

Why Choose Us

1.We have professional engineers, top teams and state-of-the-art technology to ensure product quality.

2.We have a history of more than 30 years of development, we have a lot of investment in grease machines, and there are many innovative machines that are at the forefront of technology.

3.Our machines have a particularly high utilization rate of raw materials, high oil yield and good quality.

The Advantages

(a)Residual oil rate in the dry meal is low.

(b)Improving the quality of the oil.

(c)Low processing cost, high labor productivity.

(d)High automatic and labor saving.

And more other advantages please contact me now, we will provide profession program for you, and we accept custom according your requirements.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.if the amount of goods to be deliverd is relatitively small ,the goods will be packaged in the form of export wooden boxes .if the goods are shipped in the large quantities,the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one. Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

2.Top production team

3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!