Small Scale Sunflower Oil Press Milling Plant in South Africa

- usage: small scale cooking oil refinery machine

- max capacity: 50tpd

- weight: 2000 KG

- warranty: 1 Year

- oil type: Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- key selling points: Long Service Life

- Product name: Cooking sunflower oil refinery plant manufacturer

- Raw material: Sunflower,soybean,groundnut,mustard,etc.

- Keyword 1: Sunflower oil milling machine

- Keyword 2: Small scale cooking oil refinery machine

- Package: Standard Wooden Case

- Capacity: 1TPD-1000TPD

- Character: High Yield Efficiency

- Factory visit: welcome

- Extraction of Oilseeds: 95% Oil Yield

- MOQ: 1 Set

- Selling Units: Single item

- Single package size: XX cm

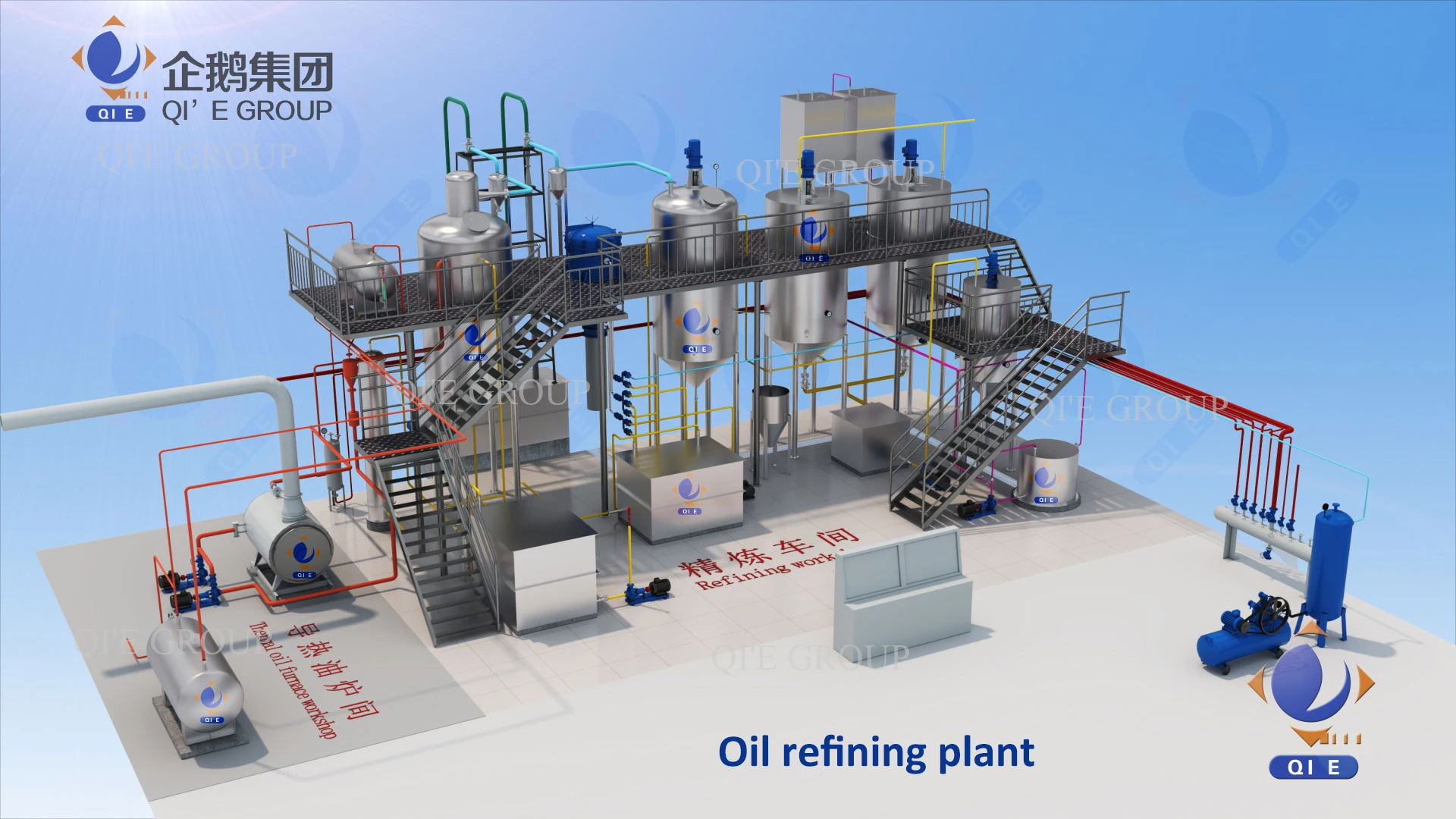

Small Scale Sunflower Oil Press Milling Plant in South Africa

Crude oil refining is an important part of edible oil manufacturing. Oil refining machine can remove mechanical impurities, solute impurities, pigments, moisture, and free fatty acids in grease. Our oil refining machine is suitable to all kinds of oil, eg: rice bran, palm, sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

According to the raw materials and capacity, we can use batch, continuous, physical and chemical refining design. The product oil can reach first to fourth grade. Guarantee the highest quality and lowest cost.

Flow chart of cooking sunflower oil press milling plant cooking oil refinery machine line:

Crude Oil→ Filter→ Degumming→ Deacidification→ Decoloring→ Deodorizing→ Dewaxing→ Defeat→ First Grade Oil

Centrifugal classifier

Condenser

Hydration tank

Deodorizing tank

Dewaxing

Fatty acids catcher

The main Production introduction of cooking sunflower oil press milling plant cooking oil refinery machine line:

1. Decoloring tank: bleach pigments from oil.

2. Deodorizing tank: remove the un-favored smell from decolorized oil.

3. Oil furnace: provide enough heat for the refining sections which need high temperature of 280℃.

4. Vacuum pump: provide high pressure for bleaching, deodorization which can reach 755mmHg or more.

5. Air compressor: dry the bleached clay after bleaching.

6. Filter press: filter the clay into the bleached oil.

7. Steam generator: generate steam distillation.

The processing materials cooking sunflower oil press milling plant cooking oil refinery machine line

Specification

| cooking sunflower oil press milling plant cooking oil refinery machine line | |

| Machine Type | Cooking oil refining machine |

| Automatic Grade | Automatic |

| Production Capacity | 1-1000TPD |

| Voltage | 220V/380V/440V |

| Crude Oil type | Soybean oil, Sesame oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil |

| Machine Material | Stainless Steel Oil Refinery Machine |

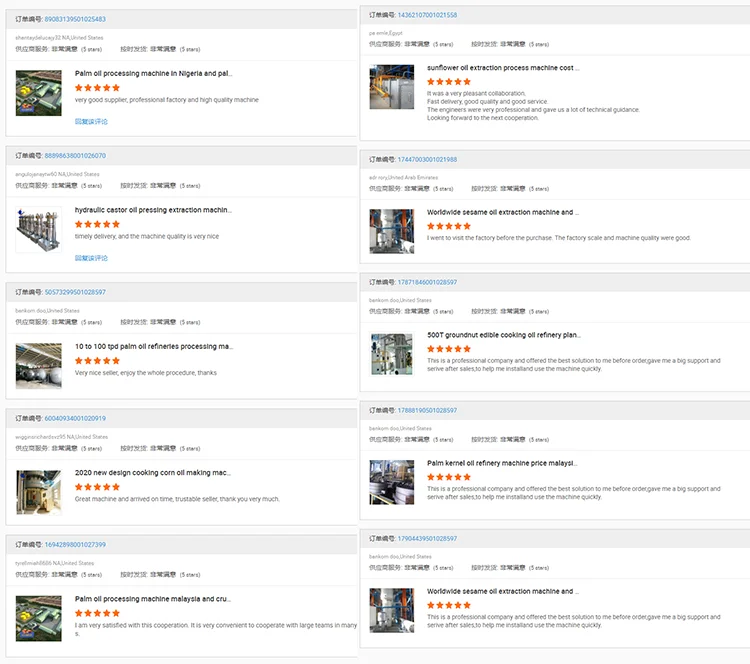

Customer Case

Sunflower oil refinery plant workshop under construction

Customer Feedback

Customer Photos

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems. If the amount of goods to be delivered is relatively small, the goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company Profile

HENAN QIE MACHINERY CO.,LTD is a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!