Sunflower Peanut Oil Processing Production Machine Plant in Kenya

- usage: sunflower oil production plant

- max capacity: 1000tpd

- weight: 2000 KG

- warranty: 1 Year

- oil type: Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, Peanut Oil, Coconut Oil, Mustard Oil, Pumpkin Oil, Corn Germ Oil

- type: Cold & Hot Processing Machine

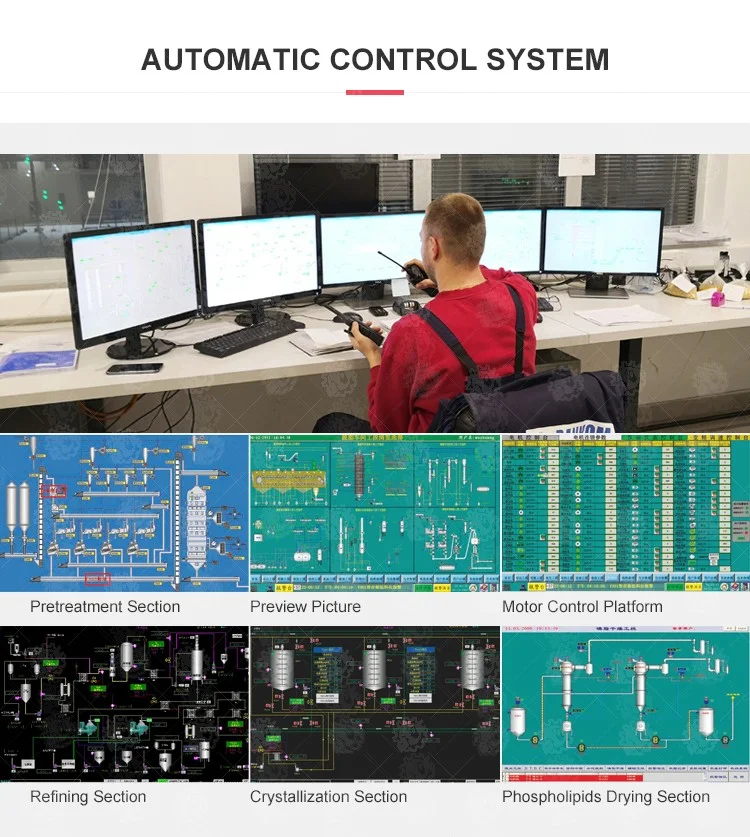

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- key selling points: Famous brand PLC

- Product name: Cooking oil extraction and refining machine

- Raw material: Sunflower,soybean,sesame,peanut,etc.

- Keyword: sunflower oil production plant

- Advantage: High Oil Press Yield Rate

- Control mode: Intelligent Control + Button

- Application range: Food Edible Oil Produce

- Power: According to capacity

- Certification: CE/ISO9001

- Factory visit: Welcome

- MOQ: 1 Set

- Packaging Details: For cooking oil extraction and refining machine: Standard international wooden boxes in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

- Supply Ability

- Supply Ability: 300 Set/Sets per Month cooking oil extraction and refining machine

Sunflower Peanut Oil Processing Production Machine Plant in Kenya

We can provide 10-1000T/D sunflower process production line, extraction and refining equipment. Factory price, Worldwide sales.

Pretreatment of sunflower oil production plant

Cleaning sieve- Destoner- Magnetic separator- Shelling&kernel separator- Flaking- Cooking

Press & Solvent extraction of sunflower oil production plant

After the pretreatment process, sunflower seed is conveyed to press machine by conveyor, then being pressed to get sunflower oil and sunflower cake.

Solvent extraction process procedure of sunflower oil production plant

Solvent extraction(extractor) -Desolventization(DTDC)-Miscella oil evaporation(Evaporator&stripper)-Solvent condensation recovery(Condenser)

Refining of sunflower oil production plant:

1. Degumming–Hydration degumming,remove the phospholipid in the oil;

2. Deacidification–Use chemical or physical methods to remove free fatty acid, keep the oil quality stable;

3. Decolorization–Add white clay, remove the deep pigment in the oil, make the oil bright;

4. Deodorization–Heat up the oil with high temperature and vacuum, remove the bad odor from the oil, keep the oil flavor pure and good smell;

5. Dewaxing–The main process includes freezing, crystallization, remove the wax fat in the oil, keep the oil flowable.

We can also provide oil processing solutions for below materials:

Henan Qi’E all kinds of oil seeds, eg: sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

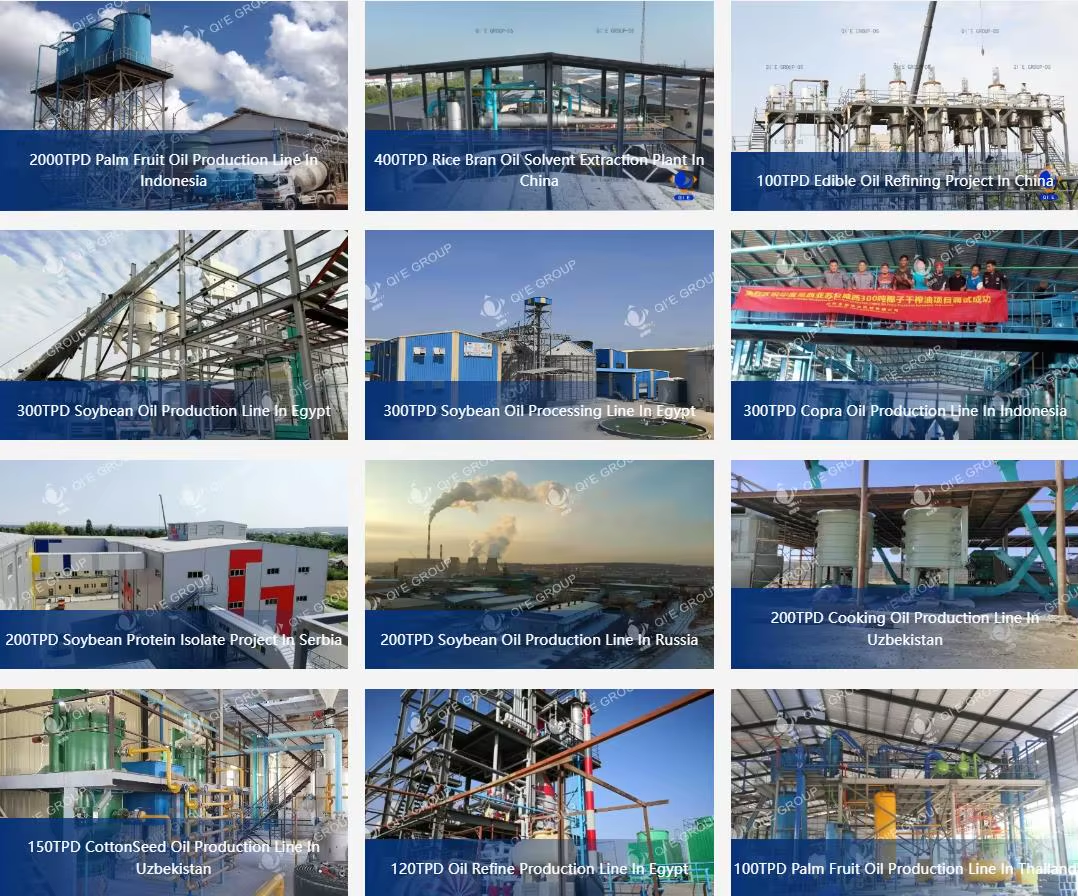

Customer Case of Sunflower Peanut Oil Processing Production Machine Plant in Kenya

Packing and Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems. Small goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, will be directly loaded into the containers and reinforced to prevent the goods from colliding.

Our Service

Company Profile

HENAN QIE MACHINERY CO.,LTD is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R&D and application of new technologies.

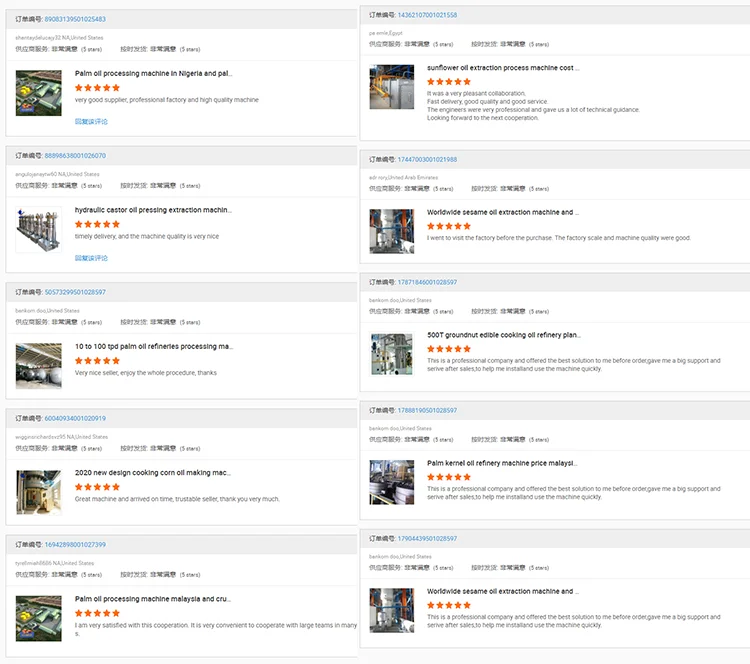

Customer Feedback

REQUEST A QUOTE

You can fill out the following form for your information needs, our technical and commercial staff will contact you. To ensure timely processing of your information, please be sure to accurately complete your contact telephone number.