Sunflower Soybean Oil Pressers Refinery / Extraction Line in Rwanda

- usage: Oil refining machine

- max capacity: 5-1000tpd

- weight: 50000 KG

- warranty: 1 Year

- oil type: Soybean Oil, Rap seed oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, Palm Oil

- type: Cooking oil refining machine

- automatic grade: Automatic

- production capacity: 5-1000TPD

- voltage: 220V/380V/440V

- key selling points: Multifunctional

- Product name: Multifunctional Cooking Oil Pressers Refinery / Extraction Line

- Raw material: Crude Edible Oil

- Keyword 1: Oil Pressers

- Keyword 2: Cooking Oil Making Machine for Industrial Sunflower

- Machine Material: Stainless Steel

- Advantage: Low Consumption High Efficiency

- Function: Hot Press

- Color: Customers' Requirements

- MOQ: 1 Set

- Character: High Yield Efficiency

- Packaging Details: For oil refining machine: Standard international wooden boxes in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

- Supply Ability

- Supply Ability: 100 Set/Sets per Month

Our company produces and develops different types of equipment, there are stand-alone and production line. The single machine includes palm oil press, screw oil press and hydraulic oil press. The production line includes oil refining plant and solvent oil extraction plant.

Hydraulic Oil Press Machine

Hydraulic oil press machine can directly squeeze oil after adding the oil seeds into the oil barrel. Working procedure only takes 5-7 minutes.

Large Oil Press Machine

The large oil press machine is a continuous oil expeller which is suitable for pre-pressing and or twice pressing process in small and medium scaled oil plant

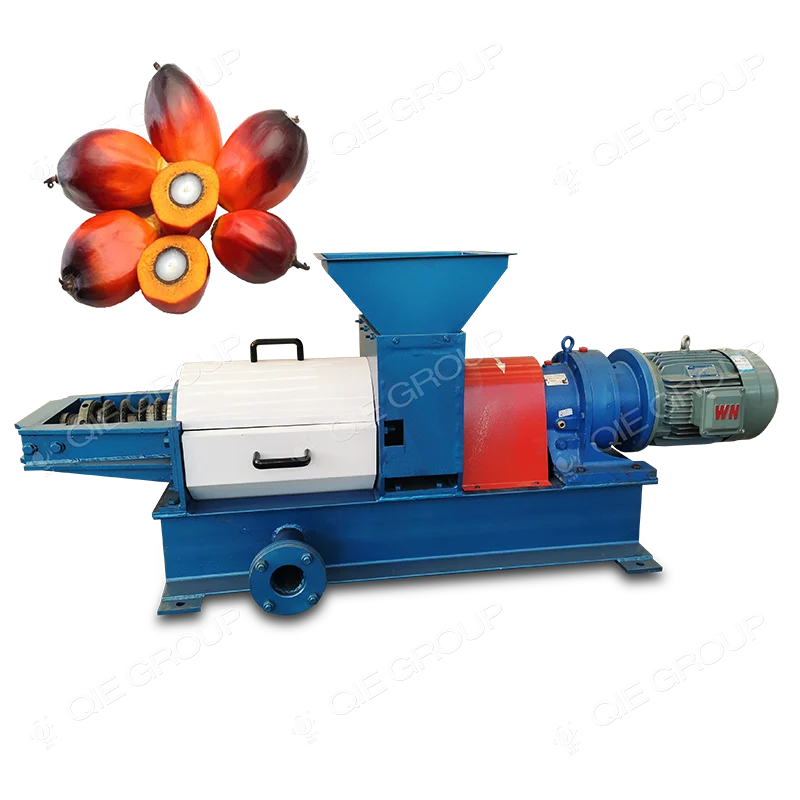

Palm Oil Press Machine

Palm fruit contains palm kernels, which cannot be broken during the pressing process. Therefore, palm fruit oil press is different from other oil presses.

Screw Oil Press Machine

Raw materials can directly feed into the machine by hot or cold press, and press machine with filter drum in one set, so crude oil is clean and pure after filtering,

Oil Refinery Plant

Oil refining technology and complete sets of equipment are suitable for the processing of various vegetable oils and animal oils. According to the raw material and capacity, we can use batch, continuous, physical and chemical refining design.

Oil Solvent Extraction Plant

Oil extraction plant mainly includes Rotocel extractor, Loop type extractor, and Towline extractor. According to different raw material, we adopt different machine types, we adopt D.T.D.C Desolventizer machine, Full negative pressure evaporation and paraffin recycling equipment.

Main business field

1.10-500T/H oil material first cleaning, drying and storage section turnkey project.

2.100-3000T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing, soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos direct puffing). Rice bran production line turnkey project.

3.100-3000T/D leaching workshop turnkey project (towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

4.30-100T/D oil continuous grade one or two physical (chemical)refining production line.

5.20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project.

6.10-200T/D fatty acid esterification production cooking oil production line.

7. 1TPH-120TPH Palm Fruit Processing Line and Palm Kernel Processing Line.

Available oil crops

Our Service

Pre- sale

System evaluation:

1. Project basic situation; Solution: 1. The investment budget; 2. Feasibility, rationality;

Product selection: 1. Factory inspection; 2 Site measurement; 3. Technical discussion; 4.Supply professional drawing and lists

Win-Win cooperation: 1. Sign the contract; 2. Establish mutual benefit, strategic cooperative partnership.

In- sale

Design evaluation: 1. Detailed technical assessment, arrangement, 2. Design of process and equipment layout,

Procurement: Strictly inspection, Optimized selection;

Installation: 1. Quality and quantity guaranteed; 2. Completion of hand Over;

Acceptance: 1. Acceptance test; 2. Accepted deliverable;

Technical training: 1.On-site installation and products training; 2. Operation skills training; 3. Maintenance training; 4.Centralized technical training.

After- sale Technical service: Long time technical service;

Accessories supplying: Supplying spare parts with cost price;

Complaint handling: 12-24 hours response mechanism;

Client Review: 1. Call-back; 2. Regular return visit.

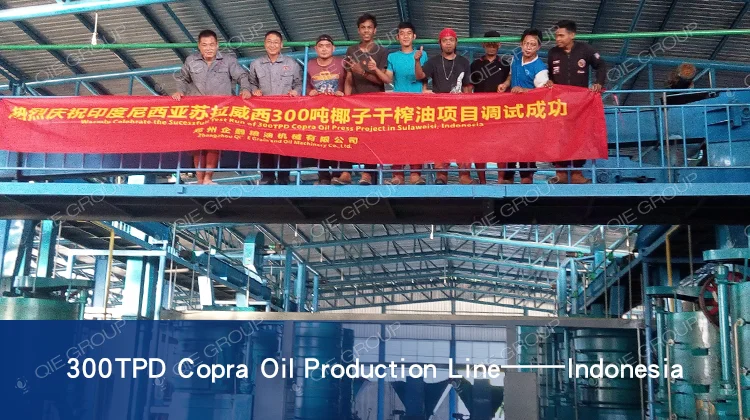

Customer Cases

Why Choose Us

QI’E Group is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College ) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc, R&D and application of new technologies.

Our company has passed ISO9001:2000 international quality management system certification. It has the qualification of manufacturing of the first and second class of pressure vessel; besides, it has obtained a number of national patents.

Customer Visit

Our company with excellence in the production process, the courage to innovate the production concept has grown rapidly into China’s grain and oil machinery production and export base, products sell well all over the country, and exported to Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Iran, North Korea and other more than 40 countries and regions.