Tanzania Sunflower Oil Making Machine Soybean Oil Production Line

- usage: SUNFLOWER OIL PRODUCTION

- max capacity: 1000tpd

- weight: 20000 KG

- warranty: 1 Year

- oil type: Soybean Oil, SESAME OIL, sunflower seed oil, Peanut Oil, Coconut Oil, Almond Oil, walnut oil, Palm Oil, OLIVE OIL

- type: Low Power Consumption Soybean Oil Machine

- automatic grade: Automatic

- production capacity: 88 Sets Monthly

- voltage: 380V or 440 V

- dimension(l*w*h): Depends On Capacity

- key selling points: Multif-unctional Soybean Oil Project

- Product name: Sunflower Oil Making Machine Soybean Oil Production Line

- Application: Sunflower Oil Production Line

- Advantage: Energy Saving

- Keyword: vegetable oil production line

- capacity: 10-1000TPD

- Equipment material: Stainless steel or carbon steel

- Raw Materials Suitable: Vegetable, Rice bran, Palm Oil Cake, Sunflower Seed,etc

- Oil Rate: 45%-60%

- Press Type: Hot Press Oil Machine

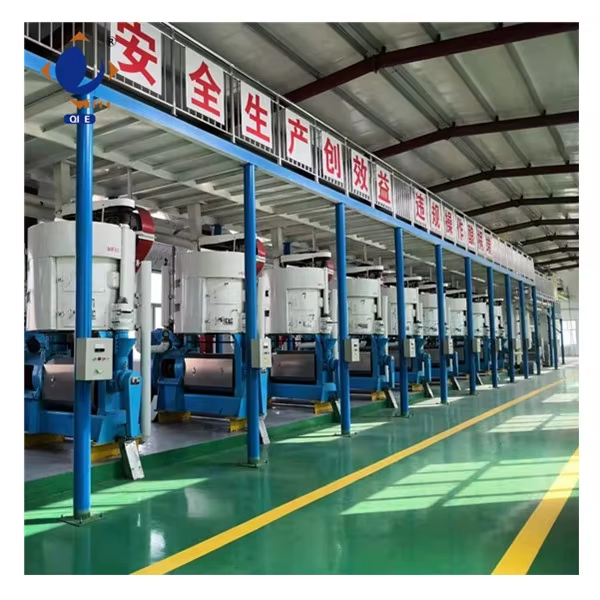

Tanzania Sunflower Oil Making Machine Soybean Oil Production Line

Tanzania Sunflower Oil Making Machine Soybean Oil Production Line including:

Oil Pretreatment and Prepressing equipment, Oil Extraction equipment, and Oil Refining equipment. We adopt different machine types, and we adopt D.T.D.C Desolventizer machine, Full negative pressure evaporation and paraffin recycling equipment at the same time. Equipment are of high quality, advanced technology, high safety, interlocking control, automatic control, stable operation, low consumption, low oil residue, and high quality final products.

| Residual oil in cake | ≤5% |

| Handling capacity | 500kg-50tons/h |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Steam consumption | ≤120Kg/T (0.8MPa) |

| Mechnical impurities | ≤ 0.3% (adjustable) |

| Moisture in crude oil | ≤ 0.2% (qualified detonated experiment |

1.Oil Pretreatment

Oil seeds — Magnetic box– Cleaning Sieve– Crusher — Flaking roll — Cooker — Oil prepressing — Cakes — Solvent Extraction workshop

2.Craft flow of solvent extraction plant

Solvent– Extractor–Mixed oil — 1st and 2nd evaporation — Stripping tower — Crude oil

| Moisture of extraction material | 5-8% |

| temperature of extraction material | 50-55°C |

| oil content of extraction material | 14-18% |

| thickness of extraction cake | less than 13mm |

| powder porosity of extraction material | less than 15% (30 mesh) |

| solvent | national standard No. 6 solvent oil |

| volume of supplement water | 1-2m/t raw material |

3.Craft flow for refining workshop

crude oil → degumming&dephosphorization → deacidification → drying → decolorization → deodorization → defatting → dewaxing → finished oil.

(1)Deacidification and degumming

This step is mainly to remove the excess acid in the grease. If the peptized impurities of the oil are not removed, the excessive emulsification will occur during the alkali refining process, so that the oil soap can not be separated well, affecting the refining and Oil quality.

(2)Decolorization

The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil. In this process, the oxide is completely removed, and the trace amount of metal, residual soap and residual fat are removed in a maximum amount, and a part of the pigment is moderately removed.

(3)Deodorization

Deodorization of oil and fat not only removes odor substances in oil, but also improves the smoke point of oils and fats, improves the flavor of edible oils, and effectively improves the safety of oils and fats.

(4)Filteration

Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter, then enters into fine filter, in which clay and fixed impurities are blocked.

(5)Dewaxing process

Bleached sunflower seed oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization process, this process is controlled by the computer through the parameters, pre-established the computer controls temperature of circulating water in the frozen coil to comand cooling speed of the oil, thereby receive the best crystal result.

Our cooking oil process line could press many different raw materials, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

Company

Zhengzhou Qi’E Grain&Oil Machine Co Ltd is located in Zhengzhou City, Henan Province, China, and has strong strength in grease machines.

1. more than 30 years of experience

The factory is located in Henan Province, China. We are very welcome to visit our factory. If you need it, we will arrange a pick-up.

2.top production team

The equipment will be inspected by special personnel before transportation. The transportation and packaging will be packaged in international standards. If you have special packaging requirements, please contact our business manager, we will give you the most suitable solution.

3.high quality products in production process, Our sales manager will send you a production progress picture or video every day, so that you can know the production progress of the product in real time, and we accept L/C payment.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.If the amount of goods to be delivered relatively is small, the goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.